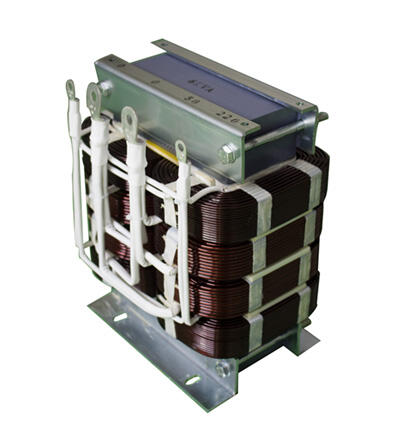

energy efficient dry transformer

Energy efficient dry transformers represent a significant advancement in power distribution technology, combining superior performance with environmental responsibility. These transformers operate without liquid cooling mediums, instead utilizing air and high-grade insulation materials for cooling and isolation. The core is constructed with high-quality silicon steel laminations, precisely cut and assembled to minimize energy losses. These transformers typically operate at efficiencies exceeding 98%, significantly reducing energy waste during power distribution. The design incorporates advanced vacuum pressure impregnation (VPI) technology, ensuring excellent insulation properties and heat dissipation characteristics. Their modular construction allows for easy installation and maintenance, while the absence of oil eliminates the risk of environmental contamination and reduces fire hazards. These transformers are particularly well-suited for indoor installations, commercial buildings, renewable energy projects, and industrial applications where safety and reliability are paramount. They operate across a wide range of voltages, typically from 480V to 34.5kV, with power ratings from 15 kVA to 3000 kVA. The transformers feature sophisticated monitoring systems that provide real-time performance data, enabling proactive maintenance and optimal operation.