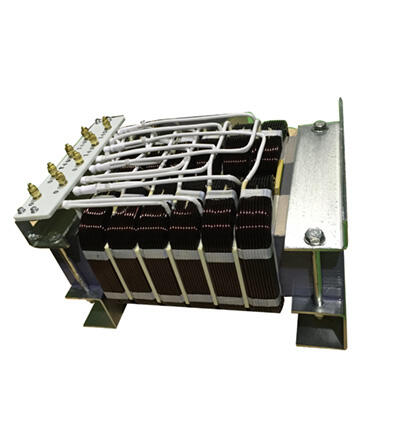

ecofriendly dry transformer

The ecofriendly dry transformer represents a significant advancement in electrical power distribution technology, combining environmental responsibility with operational efficiency. This innovative transformer operates without liquid insulation, instead utilizing high-quality insulating materials and advanced air cooling systems. The design incorporates environmentally friendly materials that are both recyclable and free from hazardous substances. Operating at voltages ranging from low to medium levels, these transformers effectively convert electrical energy while maintaining minimal environmental impact. The core technology employs vacuum pressure impregnation (VPI) process, ensuring superior insulation properties and extended service life. These transformers are particularly valuable in indoor installations, commercial buildings, renewable energy projects, and industrial applications where environmental considerations are paramount. The design features advanced thermal management systems that optimize heat dissipation without requiring liquid coolants, contributing to reduced maintenance requirements and operational costs. With their compact footprint and modular design, ecofriendly dry transformers offer flexible installation options while meeting stringent environmental standards and safety regulations.