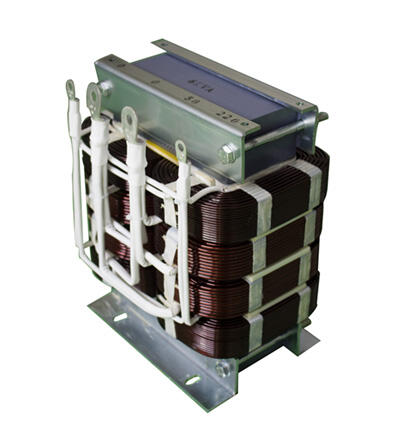

high efficiency control transformer

A high efficiency control transformer is an advanced electrical device engineered to provide precise voltage transformation while maintaining exceptional energy efficiency. These specialized transformers are designed to convert primary voltage to a lower secondary voltage with minimal power loss, making them essential components in various control and automation systems. The transformer's core is typically constructed using high-grade silicon steel laminations that minimize eddy current losses and optimize magnetic flux distribution. The copper windings are precision-wound to reduce resistance losses and ensure optimal performance across varying load conditions. These transformers feature enhanced insulation systems that provide superior thermal management and electrical isolation, contributing to their long-term reliability and safety. The design incorporates advanced magnetic shielding to minimize electromagnetic interference, ensuring clean power output for sensitive control equipment. Modern high efficiency control transformers often achieve efficiency ratings above 95%, significantly reducing energy waste and operating costs. They are commonly deployed in industrial automation, HVAC systems, lighting controls, and various manufacturing processes where precise voltage regulation and energy efficiency are paramount.