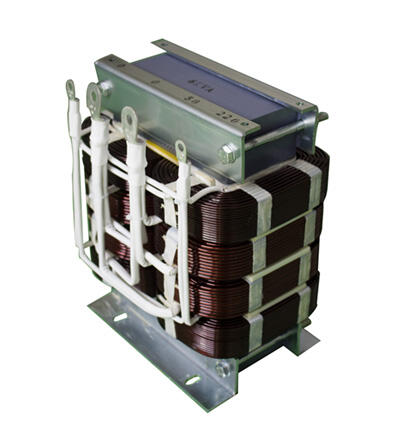

control transformer for industrial use

A control transformer is a specialized type of transformer designed specifically for industrial control circuits and automation systems. These devices play a crucial role in providing precise voltage control and electrical isolation for industrial equipment. Control transformers are engineered to maintain consistent output voltage under varying load conditions, ensuring stable operation of control circuits, solenoids, relays, and other industrial control devices. The design incorporates advanced features such as high inrush capability, excellent voltage regulation, and robust short-circuit protection. These transformers typically operate with primary voltages of 120V to 480V and secondary voltages of 12V to 24V, making them ideal for powering control circuits in manufacturing facilities, processing plants, and automated production lines. The core construction utilizes high-grade silicon steel laminations to minimize energy losses and maintain high efficiency. Safety features include thermal protection, overload protection, and isolation between primary and secondary windings. Most control transformers are designed to handle inrush currents up to 10 times the normal full load current, ensuring reliable operation during equipment startup. They also feature compact designs that facilitate easy installation in control panels and electrical enclosures while maintaining adequate ventilation for thermal management.