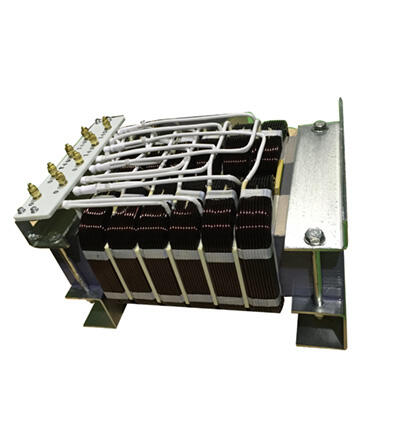

industrial dry transformer

Industrial dry transformers represent a crucial advancement in power distribution technology, offering a safer and more environmentally conscious alternative to traditional oil-filled transformers. These transformers utilize high-quality insulation materials and advanced cooling systems to transform voltage levels efficiently without the need for liquid coolants. The core technology employs vacuum pressure impregnation (VPI) process, where epoxy resin encapsulates the windings, ensuring superior insulation and protection against environmental factors. Modern industrial dry transformers operate across a wide range of voltages, typically from 480V to 34.5kV, making them versatile for various industrial applications. They feature sophisticated monitoring systems that provide real-time performance data and temperature control, ensuring optimal operation and extended service life. These transformers excel in indoor installations, particularly in areas where fire safety and environmental concerns are paramount, such as hospitals, data centers, and manufacturing facilities. The design incorporates advanced cooling mechanisms through natural air circulation or forced ventilation, eliminating the need for maintenance-intensive cooling systems. With their compact footprint and modular construction, industrial dry transformers offer flexible installation options while maintaining high efficiency ratings of up to 98%.