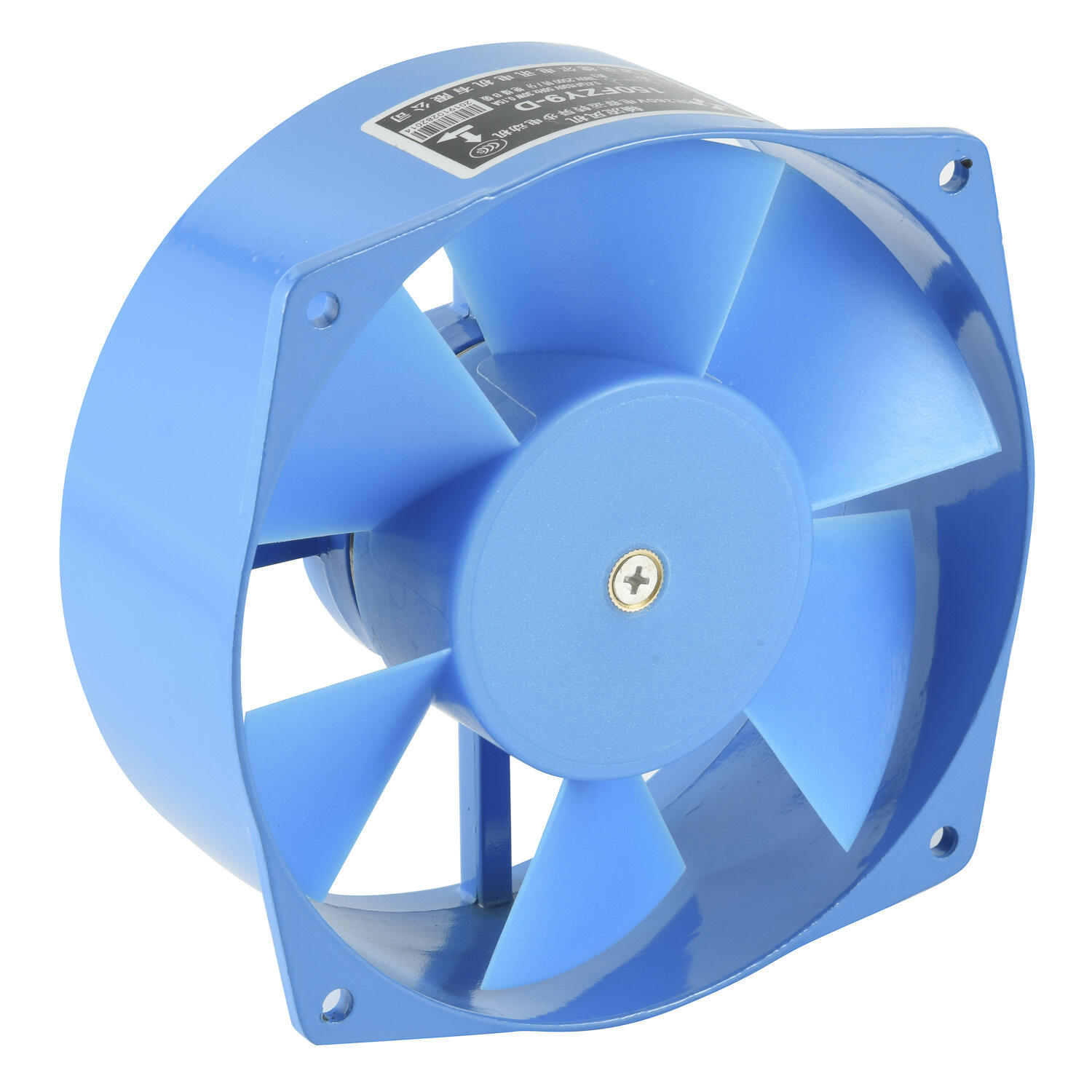

axial ventilation fan

An axial ventilation fan is a sophisticated mechanical device designed to move air parallel to its rotating shaft, making it an essential component in various industrial and commercial applications. This versatile fan operates by utilizing specially designed blades that rotate around a central hub, creating airflow in a direction parallel to the axis of rotation. The fan's design incorporates aerodynamically optimized blades, precision-engineered motors, and robust housing materials to ensure efficient air movement and long-term reliability. Modern axial ventilation fans often feature variable speed controls, enabling precise airflow adjustment to meet specific ventilation requirements. These fans excel in applications requiring high volume airflow with moderate pressure capabilities, making them ideal for ventilation systems in buildings, cooling towers, and industrial processes. The construction typically includes corrosion-resistant materials and sealed bearings, ensuring durability in challenging environments. Advanced models may incorporate smart controls, energy-efficient motors, and noise reduction technologies, addressing contemporary demands for sustainable and quiet operation. Their modular design facilitates easy installation and maintenance, while their compact profile allows for installation in space-constrained areas.