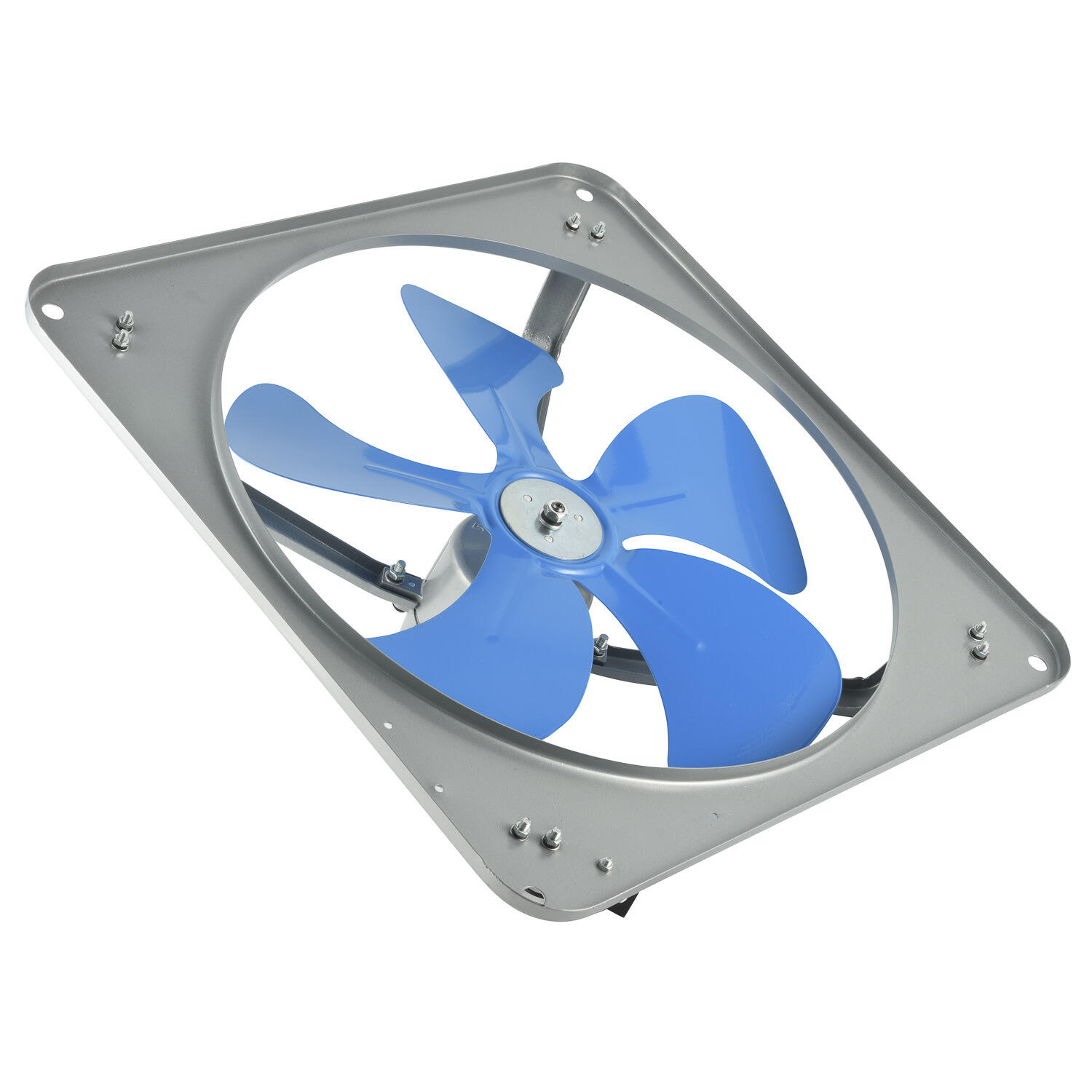

axial air fan

An axial air fan represents a vital piece of industrial and commercial ventilation equipment that moves air parallel to its rotating shaft. This highly efficient device consists of blades mounted around a central hub, operating similarly to a propeller. The fan draws air in through its intake and propels it axially through the outlet, creating a powerful, directional airflow. Modern axial air fans incorporate advanced blade designs, precision-engineered components, and cutting-edge motor technology to deliver optimal performance. These fans excel in applications requiring high volume airflow with moderate pressure capabilities, making them ideal for ventilation systems, cooling towers, and industrial processes. The design allows for customization of blade pitch angles, number of blades, and motor specifications to meet specific requirements. Axial fans are particularly valued for their space-efficient design, as their in-line configuration requires minimal installation space compared to other fan types. They operate effectively across various speed ranges and can handle temperature variations, making them versatile for different environmental conditions. The straightforward construction of axial fans also contributes to their reliability and ease of maintenance, ensuring long-term operational efficiency and reduced downtime.