axial and centrifugal fans

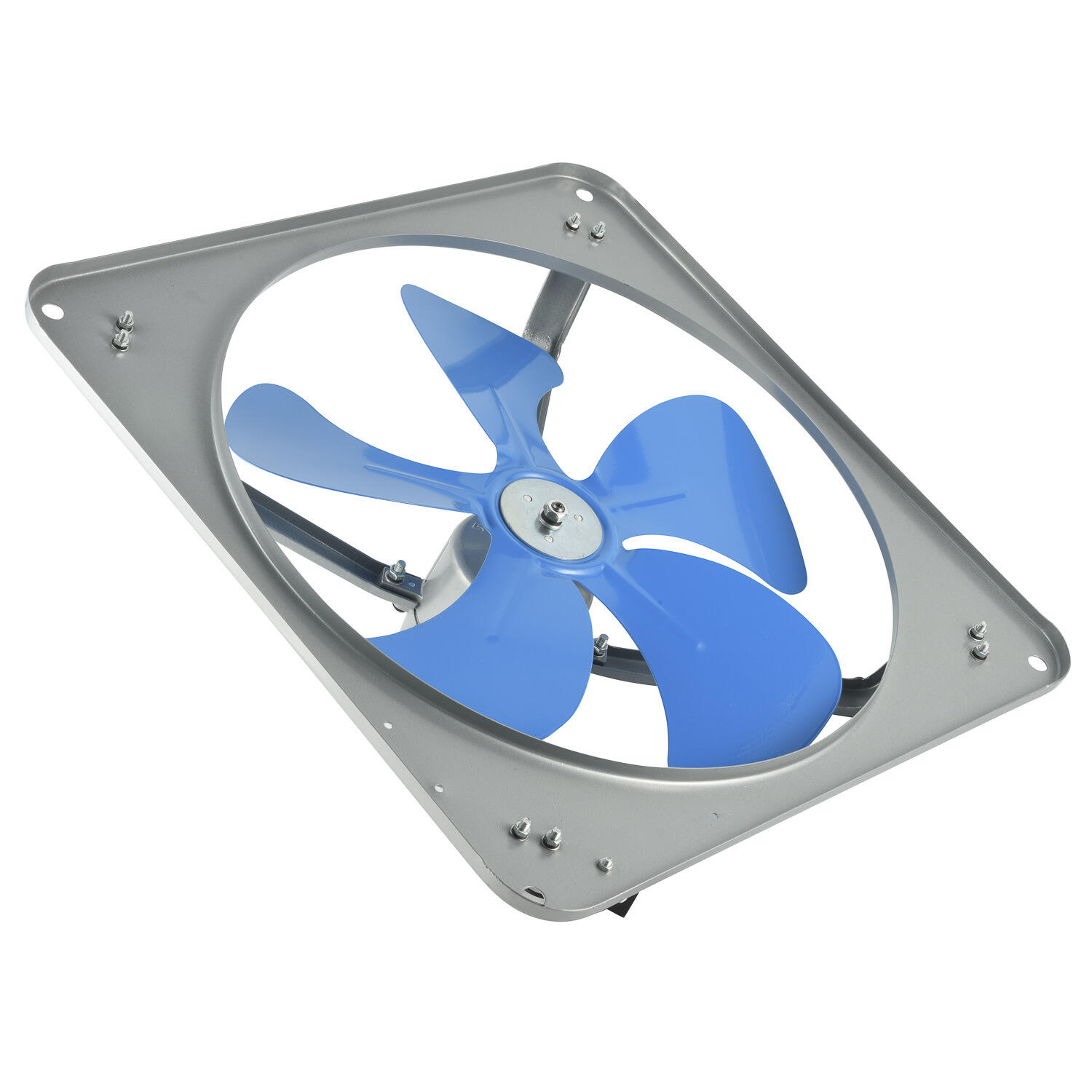

Axial and centrifugal fans are essential components in industrial ventilation and air movement systems. Axial fans operate by moving air parallel to the shaft around which the blades rotate, creating a direct airflow pattern similar to a propeller. These fans excel in high-volume, low-pressure applications and are commonly found in HVAC systems, cooling towers, and industrial ventilation. Centrifugal fans, on the other hand, work by drawing air into the center of the wheel and discharging it outward in a radial direction, using the centrifugal force generated by rotating impellers. These fans are particularly effective in applications requiring high pressure and consistent airflow, such as industrial processes, dust collection systems, and material handling. Both types of fans incorporate advanced blade designs, precision-engineered components, and modern motor technology to ensure optimal performance and energy efficiency. The selection between axial and centrifugal fans typically depends on specific application requirements, including space constraints, noise considerations, and the desired balance between airflow volume and pressure.