Dry-type transformers require effective thermal management to maintain optimal performance and extend operational lifespan. The selection of an appropriate cooling fan represents a critical engineering decision that directly impacts transformer efficiency, reliability, and maintenance requirements. Understanding the fundamental principles of capacity matching, environmental considerations, and installation techniques enables engineers to make informed decisions that optimize system performance while minimizing operational costs.

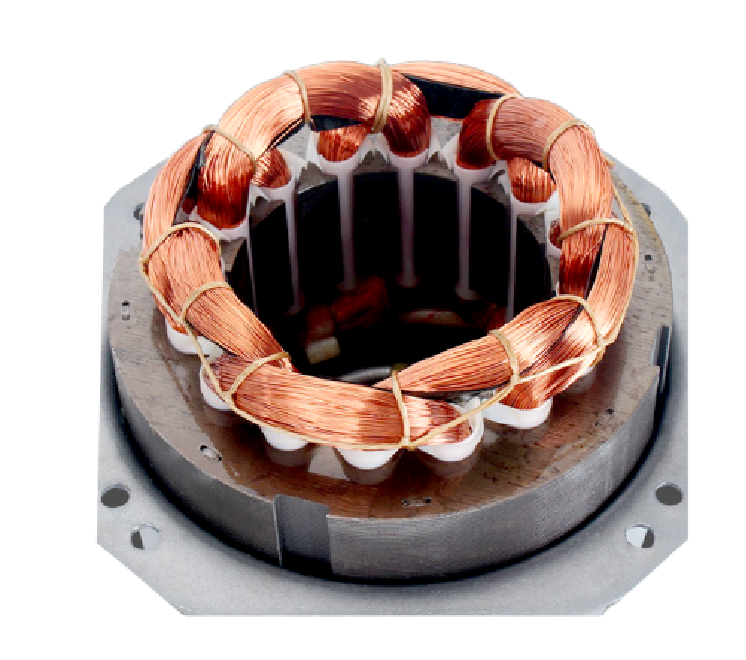

The thermal characteristics of dry-type transformers differ significantly from their oil-filled counterparts, necessitating specialized cooling solutions. Air circulation becomes the primary mechanism for heat dissipation, making the cooling fan selection process paramount to successful transformer operation. Modern industrial applications demand reliable cooling systems that can adapt to varying load conditions while maintaining consistent temperature control across diverse environmental conditions.

Understanding Dry-Type Transformer Thermal Requirements

Heat Generation Patterns in Dry-Type Transformers

Dry-type transformers generate heat through resistive losses in windings, core losses due to magnetic hysteresis, and eddy current losses within the core material. The heat generation pattern varies with load conditions, ambient temperature, and transformer design characteristics. Understanding these thermal patterns enables engineers to specify cooling fan requirements that address both steady-state and transient thermal conditions effectively.

The temperature rise in dry-type transformers follows predictable patterns based on load current, ambient conditions, and thermal time constants. Winding temperatures typically represent the limiting factor for transformer capacity, with insulation class determining maximum allowable operating temperatures. A properly selected cooling fan system ensures that temperature rises remain within acceptable limits while providing adequate safety margins for varying operational conditions.

Thermal Design Considerations

Effective thermal design requires comprehensive analysis of heat transfer mechanisms including convection, conduction, and radiation. Natural convection provides baseline cooling for many dry-type transformers, while forced air circulation through cooling fans enhances heat dissipation capacity significantly. The thermal resistance between winding surfaces and ambient air determines the temperature differential required to dissipate generated heat effectively.

Thermal modeling techniques enable engineers to predict temperature distributions within transformer assemblies under various cooling scenarios. These models consider factors such as winding geometry, core configuration, enclosure design, and ambient conditions to establish cooling requirements. Accurate thermal analysis forms the foundation for cooling fan selection and system optimization strategies.

Capacity Matching Principles for Cooling Systems

Calculating Cooling Requirements

Cooling capacity requirements depend on transformer losses, desired temperature rise limits, and environmental conditions. Total losses include no-load losses occurring continuously and load losses that vary with transformer utilization. The cooling fan system must accommodate peak loss conditions while providing efficient operation during typical load scenarios.

Heat dissipation calculations require accurate loss data from transformer manufacturers, including segregated loss components for various load conditions. Environmental factors such as ambient temperature, altitude, and air density affect cooling system performance and must be incorporated into capacity calculations. Safety factors account for uncertainties in loss calculations, ambient condition variations, and aging effects on cooling system performance.

Airflow Requirements and Distribution

Airflow requirements depend on the temperature difference between transformer surfaces and ambient air, as well as the heat transfer coefficient for the specific cooling configuration. Forced air cooling systems must provide sufficient airflow volume to maintain acceptable temperature rises while ensuring uniform air distribution across heat-generating surfaces. Inadequate airflow distribution can result in localized hot spots that compromise transformer performance and reliability.

Air distribution systems require careful design to ensure effective cooling of all transformer components. Ducting arrangements, fan placement, and air inlet/outlet configurations significantly impact cooling effectiveness. Computational fluid dynamics analysis helps optimize air distribution patterns and identify potential areas of inadequate cooling that could lead to premature failure or reduced capacity.

Environmental Adaptation Strategies

Temperature Range Considerations

Cooling fan systems must operate reliably across the full range of ambient temperatures encountered in the installation environment. High ambient temperatures increase cooling requirements while potentially reducing fan performance due to decreased air density and increased motor operating temperatures. Low ambient temperatures may reduce cooling requirements but can affect fan motor performance and introduce condensation concerns.

Temperature compensation strategies ensure consistent cooling performance across varying ambient conditions. Variable speed cooling fan controls adjust airflow rates based on actual cooling requirements, improving energy efficiency while maintaining adequate thermal protection. Temperature sensors provide feedback for automatic control systems that optimize cooling fan operation in response to changing conditions.

Humidity and Contamination Protection

Environmental humidity levels affect both transformer insulation properties and cooling system performance. High humidity environments require enhanced protection against moisture ingress that could compromise electrical insulation or cause corrosion in cooling system components. Condensation prevention measures become critical in applications with significant temperature variations or high humidity levels.

Contamination protection involves selecting cooling fan components and filtration systems appropriate for the specific environmental conditions. Industrial environments may contain airborne particles, corrosive gases, or other contaminants that can degrade cooling system performance or cause premature failure. Air filtration systems protect both transformer windings and cooling fan components from harmful environmental contaminants.

Installation Techniques and Best Practices

Mounting and Positioning Strategies

Proper cooling fan mounting ensures effective heat dissipation while minimizing vibration transmission and acoustic noise. Mounting systems must provide secure attachment while accommodating thermal expansion and operational vibrations. Positioning strategies consider airflow patterns, maintenance accessibility, and protection from environmental hazards such as moisture or mechanical damage.

Vibration isolation techniques prevent transmission of cooling fan vibrations to transformer structures or building foundations. Flexible mounting systems accommodate thermal expansion while maintaining proper alignment and air gap clearances. Anti-vibration materials and isolation mounts reduce noise transmission and extend cooling system service life by minimizing stress concentrations.

Electrical Integration and Control Systems

Electrical integration involves connecting cooling fan motors to appropriate power supplies and control systems. Motor protection devices prevent damage from electrical faults, while monitoring systems provide operational status feedback and alarm capabilities. Control integration enables automatic cooling fan operation based on transformer temperature or load conditions.

Advanced control systems optimize cooling fan operation through variable speed drives and intelligent control algorithms. These systems balance cooling effectiveness with energy consumption while providing predictive maintenance capabilities through operational monitoring and trending. Remote monitoring capabilities enable centralized control and maintenance scheduling for multiple transformer installations.

Performance Optimization and Maintenance

Operational Monitoring and Diagnostics

Continuous monitoring systems track cooling fan performance parameters including motor current, vibration levels, and airflow rates. Diagnostic systems identify developing problems before they result in cooling system failure or reduced transformer performance. Trending analysis enables predictive maintenance scheduling and optimization of cooling system operation.

Temperature monitoring throughout the transformer assembly provides feedback on cooling system effectiveness and identifies areas requiring attention. Multiple temperature sensors enable comprehensive thermal mapping and early detection of cooling system degradation or blocked airflow paths. Data logging systems maintain historical records for performance analysis and maintenance planning.

Preventive Maintenance Protocols

Regular maintenance ensures reliable cooling fan operation and extends equipment service life. Maintenance protocols include periodic inspection of fan blades, motor bearings, and electrical connections. Air filter replacement schedules prevent contamination buildup that could reduce cooling effectiveness or increase power consumption.

Lubrication schedules for cooling fan motors prevent bearing failures and ensure smooth operation. Vibration analysis identifies developing mechanical problems that could lead to premature failure. Electrical testing verifies proper motor operation and identifies insulation degradation or connection problems that require attention.

Selection Criteria and Specifications

Performance Parameters and Standards

Cooling fan selection requires evaluation of multiple performance parameters including airflow capacity, static pressure capability, power consumption, and noise levels. Industry standards provide guidelines for cooling fan performance testing and specification requirements. Compliance with relevant standards ensures reliable performance and compatibility with transformer cooling requirements.

Environmental ratings specify cooling fan suitability for various installation conditions including temperature ranges, humidity levels, and contamination exposure. Motor enclosure ratings determine protection levels against moisture and particle ingress. Proper specification of environmental requirements ensures reliable operation throughout the expected service life.

Economic Considerations and Life Cycle Costs

Economic analysis considers initial cooling fan costs, installation expenses, and ongoing operational costs including energy consumption and maintenance requirements. Life cycle cost analysis compares alternative cooling fan options based on total ownership costs over the expected service life. Energy efficiency improvements can provide significant cost savings over the operational lifetime.

Reliability considerations impact both direct costs and indirect costs associated with transformer downtime. Higher quality cooling fan systems may justify increased initial costs through improved reliability and reduced maintenance requirements. Spare parts availability and supplier support affect long-term maintenance costs and operational continuity.

FAQ

How do I determine the correct cooling fan capacity for my dry-type transformer

Calculating cooling fan capacity requires knowledge of transformer losses, ambient operating conditions, and desired temperature rise limits. Start by obtaining loss data from the transformer manufacturer, including both no-load and load losses. Consider the maximum ambient temperature and apply appropriate safety factors. The cooling fan must provide sufficient airflow to dissipate total losses while maintaining winding temperatures within acceptable limits for the insulation class.

What environmental factors should I consider when selecting a cooling fan system

Key environmental factors include ambient temperature range, humidity levels, altitude, air quality, and potential contamination sources. High temperatures increase cooling requirements while reducing fan performance. Humidity affects insulation properties and may require condensation protection. Altitude reduces air density and cooling effectiveness. Contaminated environments require enhanced filtration and protection systems to prevent degradation of both transformer and cooling components.

How often should cooling fan systems be maintained and what does maintenance involve

Maintenance frequency depends on environmental conditions and cooling fan design, typically ranging from quarterly inspections in harsh environments to annual maintenance in clean conditions. Maintenance includes cleaning air filters, inspecting fan blades and guards, checking motor bearings and lubrication, verifying electrical connections, and testing control systems. Vibration analysis and temperature monitoring help identify developing problems before they cause failures.

What are the signs that a cooling fan system may be failing or operating inefficiently

Warning signs include increased transformer operating temperatures, unusual noise or vibration from cooling fans, reduced airflow measurements, increased motor current consumption, and frequent control system alarms. Temperature trending that shows gradual increases over time may indicate cooling system degradation. Visual inspection may reveal damaged fan blades, clogged filters, or loose mounting hardware that affects performance.

Table of Contents

- Understanding Dry-Type Transformer Thermal Requirements

- Capacity Matching Principles for Cooling Systems

- Environmental Adaptation Strategies

- Installation Techniques and Best Practices

- Performance Optimization and Maintenance

- Selection Criteria and Specifications

-

FAQ

- How do I determine the correct cooling fan capacity for my dry-type transformer

- What environmental factors should I consider when selecting a cooling fan system

- How often should cooling fan systems be maintained and what does maintenance involve

- What are the signs that a cooling fan system may be failing or operating inefficiently