Power transformers are critical components in electrical infrastructure, requiring efficient thermal management to maintain optimal performance and extend operational lifespan. The integration of advanced cooling fan systems has become essential for modern transformer installations, particularly as power demands continue to increase globally. These thermal management solutions directly impact energy efficiency, operational costs, and system reliability across industrial applications. Understanding the relationship between wind speed regulation and heat dissipation efficiency enables engineers to optimize transformer performance while reducing overall energy consumption.

Fundamentals of Transformer Thermal Management

Heat Generation Mechanisms in Power Transformers

Power transformers generate heat through multiple mechanisms during normal operation, including core losses, winding losses, and stray losses within the tank structure. Core losses, also known as no-load losses, occur continuously regardless of load conditions due to hysteresis and eddy currents in the magnetic core material. Winding losses, or load losses, increase proportionally with the square of the load current, making them the dominant heat source during peak demand periods. These thermal challenges require sophisticated cooling fan solutions to maintain safe operating temperatures and prevent accelerated aging of transformer components.

The cumulative effect of these heat sources creates temperature gradients throughout the transformer structure, with hotspot temperatures often exceeding average winding temperatures by significant margins. Modern transformer design standards recognize that every 8-10°C increase in operating temperature can halve the expected insulation life, making effective thermal management crucial for asset longevity. Advanced cooling fan systems must accommodate these varying thermal loads while maintaining energy efficiency and operational reliability across diverse environmental conditions.

Traditional Cooling Methods and Limitations

Conventional transformer cooling relied primarily on natural air circulation and basic forced-air systems with fixed-speed fans that operated continuously during loading periods. These traditional approaches often resulted in excessive energy consumption during light load conditions and insufficient cooling during peak demand periods. The lack of dynamic response to actual thermal conditions led to either overcooling with wasted energy or potential overheating risks during unexpected load increases.

Oil-filled transformers traditionally used pump-driven oil circulation combined with radiator banks and constant-speed cooling fans to dissipate heat. While effective for steady-state conditions, these systems lacked the flexibility to adjust cooling capacity based on real-time thermal requirements. The energy consumption of continuously operating cooling fans often represented 2-5% of transformer losses, creating opportunities for significant efficiency improvements through intelligent speed regulation and control strategies.

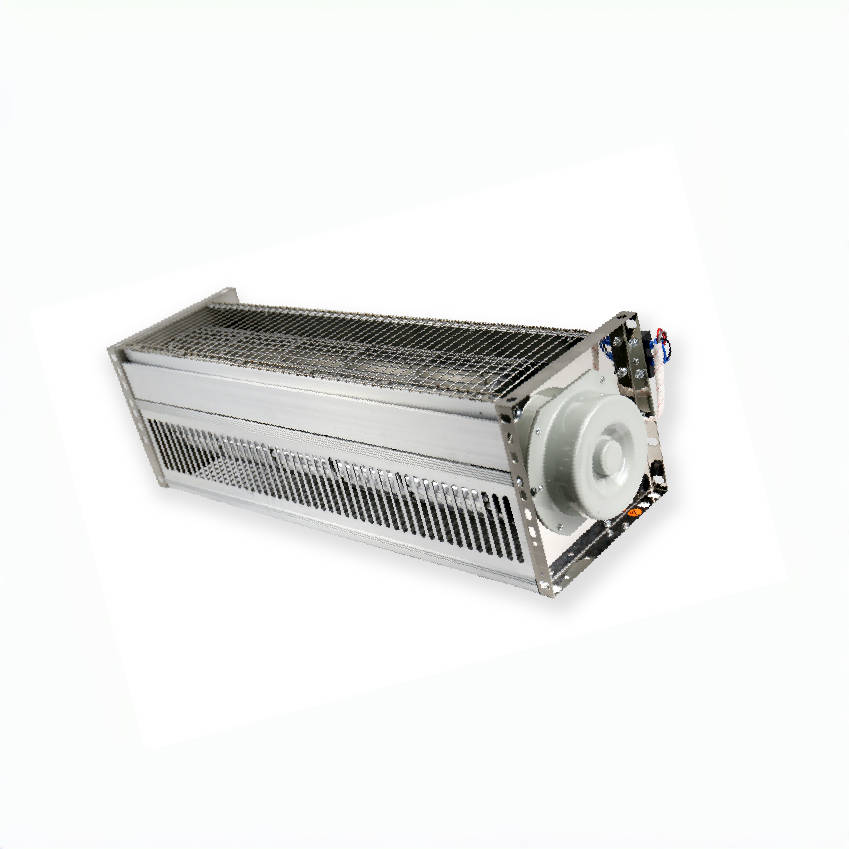

Advanced Cooling Fan Technologies

Variable Speed Drive Integration

Modern transformer installations increasingly incorporate variable frequency drives to control cooling fan speed based on actual thermal conditions rather than fixed operational schedules. These systems utilize temperature sensors strategically placed throughout the transformer to monitor winding temperatures, oil temperatures, and ambient conditions. The integration of intelligent control algorithms enables precise fan speed modulation that maintains optimal cooling while minimizing energy consumption during varying load conditions.

Variable speed cooling fan systems typically reduce energy consumption by 30-60% compared to fixed-speed alternatives while providing superior thermal control. The implementation of soft-start capabilities reduces mechanical stress on fan motors and associated infrastructure, extending equipment life and reducing maintenance requirements. Advanced drive systems also provide comprehensive diagnostic capabilities, enabling predictive maintenance strategies and improved system reliability.

High-Efficiency Motor Technologies

Contemporary transformer cooling applications utilize premium efficiency motors that exceed standard efficiency requirements by significant margins. These motors incorporate advanced magnetic materials, optimized winding configurations, and precision manufacturing techniques to minimize losses during operation. The combination of high-efficiency motors with intelligent speed control creates synergistic effects that maximize overall system efficiency while maintaining precise thermal management capabilities.

Permanent magnet synchronous motors are increasingly deployed in critical cooling applications due to their superior efficiency characteristics and precise speed control capabilities. These motors maintain high efficiency across wide speed ranges, making them ideal for variable-speed cooling applications where fan speeds may vary from 20% to 100% of rated capacity. The integration of advanced bearing technologies and aerodynamic fan blade designs further enhances overall system efficiency and operational reliability.

Wind Speed Regulation Strategies

Temperature-Based Control Algorithms

Sophisticated temperature-based control algorithms form the foundation of modern transformer cooling fan regulation systems. These algorithms process multiple temperature inputs including top oil temperature, winding hotspot temperature, and ambient air temperature to calculate optimal fan speeds for current operating conditions. The implementation of predictive algorithms that anticipate thermal loads based on historical data and weather forecasts enables proactive cooling adjustments that prevent temperature excursions.

Advanced control systems incorporate multiple temperature zones with independent fan control groups to address non-uniform heat distribution within large power transformers. The utilization of thermal modeling software enables precise prediction of temperature responses to cooling adjustments, allowing for optimized fan operation that maintains target temperatures with minimal energy expenditure. These systems typically include safety overrides that ensure adequate cooling during sensor failures or unexpected operating conditions.

Load-Following Control Methods

Load-following control strategies adjust cooling fan operation based on actual transformer loading conditions rather than solely relying on temperature feedback. These systems utilize real-time power flow data to anticipate thermal loads and preemptively adjust cooling capacity before temperature increases occur. The integration of load forecasting algorithms enables cooling systems to prepare for predicted load changes, maintaining optimal thermal conditions during dynamic loading scenarios.

Intelligent load-following systems incorporate machine learning algorithms that continuously refine cooling strategies based on observed system behavior and environmental conditions. These adaptive systems recognize patterns in load profiles, ambient temperature variations, and seasonal changes to optimize cooling fan operation for specific installation conditions. The implementation of predictive cooling strategies typically reduces peak temperatures by 5-15°C while maintaining significant energy savings compared to reactive temperature-based control alone.

Heat Dissipation Efficiency Optimization

Aerodynamic Design Improvements

Modern cooling fan designs incorporate advanced aerodynamic principles to maximize heat transfer efficiency while minimizing energy consumption and noise generation. Computational fluid dynamics modeling enables optimization of blade geometry, hub configurations, and housing designs to achieve maximum airflow with minimal pressure losses. The implementation of swept blade designs and optimized tip clearances significantly improves fan efficiency across the entire operating speed range.

Advanced materials including composite fan blades and lightweight aluminum housings contribute to improved efficiency and reduced maintenance requirements. These materials enable higher rotational speeds and improved fatigue resistance while maintaining structural integrity under varying environmental conditions. The integration of aerodynamic shrouds and optimized air intake designs further enhances overall system efficiency by reducing turbulence and improving airflow distribution across heat exchange surfaces.

Heat Exchange Surface Optimization

Effective heat dissipation requires optimization of both cooling fan performance and heat exchange surface design to achieve maximum thermal transfer rates. Modern transformer installations incorporate enhanced radiator designs with increased surface area, improved fin geometries, and optimized spacing to maximize heat transfer coefficients. The coordination between cooling fan airflow patterns and radiator configurations ensures efficient heat removal while minimizing pressure losses and energy consumption.

Advanced heat exchanger designs utilize enhanced surface treatments and micro-fin technologies to increase heat transfer rates without proportional increases in pressure drop. The implementation of variable-geometry heat exchangers that adjust surface exposure based on thermal loads enables dynamic optimization of heat dissipation capacity. These systems typically achieve 15-25% improvements in heat transfer effectiveness compared to conventional radiator designs while maintaining compatibility with existing cooling fan installations.

Energy Efficiency Measurement and Validation

Performance Monitoring Systems

Comprehensive performance monitoring systems provide real-time assessment of cooling fan efficiency and thermal management effectiveness. These systems incorporate multiple measurement points including fan power consumption, airflow rates, temperature differentials, and overall system efficiency metrics. Advanced data acquisition systems enable continuous monitoring of cooling performance trends and identification of optimization opportunities or developing maintenance requirements.

Modern monitoring systems utilize wireless sensor networks and cloud-based analytics platforms to provide remote monitoring capabilities and advanced diagnostic functions. The integration of artificial intelligence algorithms enables predictive analysis of cooling system performance and early detection of potential efficiency degradation. These systems typically provide 24/7 monitoring capabilities with automated alerts for performance deviations or maintenance requirements.

Energy Savings Quantification

Accurate quantification of energy savings requires comprehensive measurement of cooling fan power consumption before and after efficiency improvements. Advanced metering systems provide high-resolution power monitoring that captures variations in fan energy consumption across different operating conditions and load profiles. The implementation of baseline measurement periods enables accurate assessment of improvement effectiveness and return on investment calculations.

Energy savings validation typically incorporates multiple measurement parameters including fan power consumption, transformer losses, and overall system efficiency improvements. The utilization of standardized measurement protocols ensures accurate comparison of different cooling technologies and optimization strategies. Most installations achieve 25-45% reductions in cooling system energy consumption through the implementation of advanced variable-speed cooling fan systems and optimized control strategies.

Implementation Best Practices

System Integration Considerations

Successful implementation of advanced cooling fan systems requires careful consideration of existing transformer infrastructure and electrical system compatibility. The integration of variable frequency drives and advanced control systems must accommodate existing protection schemes, communication protocols, and operational procedures. Proper system integration ensures seamless operation while maintaining all safety and reliability requirements of the original transformer installation.

Effective implementation requires coordination between multiple engineering disciplines including electrical, mechanical, and control systems engineering. The development of comprehensive integration plans that address power supply requirements, control signal routing, and operator interface design ensures successful project execution. Advanced cooling systems typically require 6-12 months implementation timelines for complex transformer installations, including design, procurement, installation, and commissioning phases.

Maintenance and Reliability Optimization

Advanced cooling fan systems require specialized maintenance procedures to ensure optimal performance and extended operational life. Preventive maintenance programs must address variable frequency drive components, advanced sensors, and intelligent control systems in addition to traditional fan motor and mechanical components. The implementation of condition-based maintenance strategies utilizing system diagnostic capabilities enables optimized maintenance scheduling and reduced operational costs.

Reliability optimization requires redundant system designs that ensure continued cooling capability during component failures or maintenance activities. Modern installations typically incorporate multiple independent cooling fan groups with automatic failover capabilities to maintain adequate thermal management during single-point failures. The integration of comprehensive diagnostic systems enables early detection of developing problems and proactive maintenance interventions that prevent unplanned outages.

FAQ

What are the primary benefits of variable speed cooling fan systems for transformers

Variable speed cooling fan systems provide significant energy savings typically ranging from 30-60% compared to fixed-speed alternatives, while offering superior thermal control and extended equipment life. These systems automatically adjust fan speeds based on actual thermal conditions, preventing overcooling during light loads and ensuring adequate cooling during peak demand periods. Additional benefits include reduced noise levels, lower maintenance requirements, and improved system reliability through intelligent diagnostic capabilities.

How do advanced control algorithms improve cooling system efficiency

Advanced control algorithms optimize cooling fan operation by processing multiple temperature inputs and load conditions to calculate optimal fan speeds for current operating requirements. These systems incorporate predictive capabilities that anticipate thermal loads based on historical data and forecasted conditions, enabling proactive cooling adjustments. Machine learning algorithms continuously refine control strategies based on observed system behavior, typically achieving 15-25% additional efficiency improvements compared to basic temperature-based control systems.

What maintenance considerations apply to modern transformer cooling systems

Modern transformer cooling systems require specialized maintenance procedures that address variable frequency drives, advanced sensors, and intelligent control components in addition to traditional mechanical elements. Condition-based maintenance strategies utilizing system diagnostic capabilities enable optimized maintenance scheduling and early detection of developing problems. Typical maintenance intervals range from quarterly inspections for critical components to annual comprehensive system evaluations, with most systems providing 15-20 year operational life when properly maintained.

How can energy savings from cooling system improvements be accurately measured

Energy savings measurement requires comprehensive monitoring of cooling fan power consumption using high-resolution metering systems that capture variations across different operating conditions. Baseline measurement periods of 3-6 months before improvements provide accurate comparison data, while post-implementation monitoring validates actual savings achieved. Most installations utilize standardized measurement protocols that include fan power consumption, transformer losses, and overall system efficiency metrics to ensure accurate savings quantification and return on investment calculations.

Table of Contents

- Fundamentals of Transformer Thermal Management

- Advanced Cooling Fan Technologies

- Wind Speed Regulation Strategies

- Heat Dissipation Efficiency Optimization

- Energy Efficiency Measurement and Validation

- Implementation Best Practices

-

FAQ

- What are the primary benefits of variable speed cooling fan systems for transformers

- How do advanced control algorithms improve cooling system efficiency

- What maintenance considerations apply to modern transformer cooling systems

- How can energy savings from cooling system improvements be accurately measured