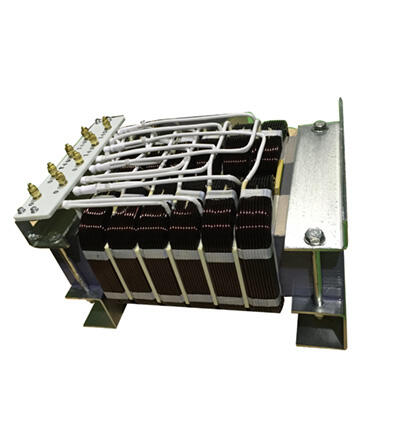

wholesale dry type transformers

Wholesale dry type transformers represent a significant advancement in power distribution technology, offering a safer and more environmentally conscious solution for various applications. These transformers utilize air as their cooling medium instead of oil, eliminating the risk of oil leaks and reducing maintenance requirements. The core construction consists of high-grade silicon steel laminations, while the windings are typically made from high-purity aluminum or copper conductors, encapsulated in class F or H insulation materials. They operate efficiently in both indoor and outdoor settings, with voltage ratings typically ranging from 480V to 35kV and power ratings from 15kVA to 5000kVA. The transformers feature advanced vacuum pressure impregnation (VPI) technology, ensuring superior insulation and protection against environmental factors. Their design incorporates multiple taps for voltage adjustment, temperature monitoring systems, and built-in protection mechanisms against overload and short circuits. These units are particularly valuable in commercial buildings, industrial facilities, renewable energy installations, and urban infrastructure projects where safety and reliability are paramount considerations.