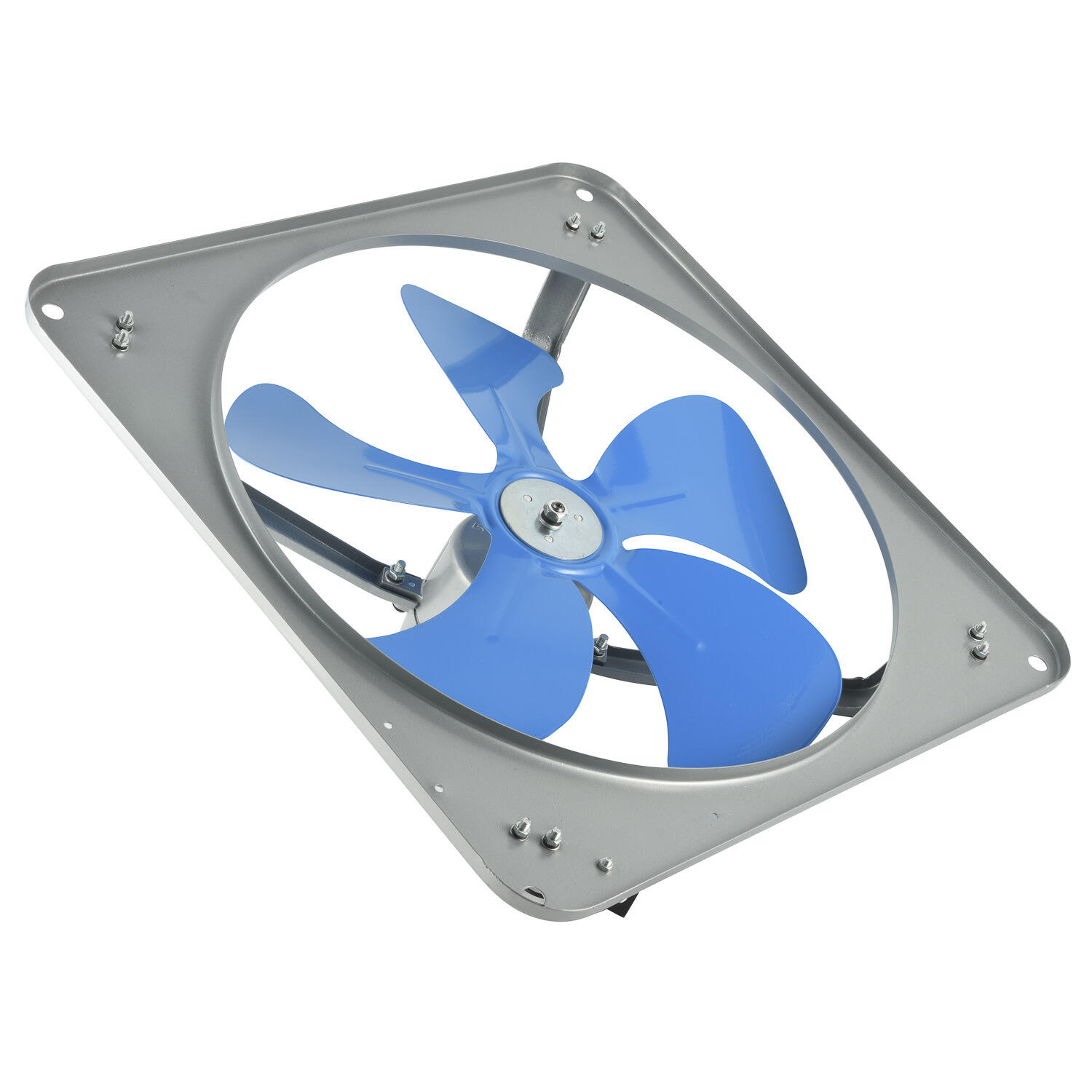

axial centrifugal fan

The axial centrifugal fan represents a groundbreaking advancement in industrial ventilation technology, combining the best features of both axial and centrifugal fan designs. This innovative hybrid solution delivers exceptional performance by utilizing a unique blade configuration that enables air to flow both axially and radially. The fan's sophisticated design incorporates specially curved blades that initially direct air flow parallel to the shaft, similar to an axial fan, before redirecting it perpendicular to the shaft like a centrifugal fan. This dual-flow capability results in higher pressure capabilities while maintaining excellent volume flow rates. The fan's construction typically features precision engineered impellers, aerodynamically optimized housing, and robust bearings to ensure reliable operation in demanding industrial environments. Applications for axial centrifugal fans span numerous industries, including HVAC systems, industrial process ventilation, clean rooms, and manufacturing facilities. These fans excel in situations requiring both high airflow and moderate pressure, making them particularly valuable in complex ventilation systems. The versatility of axial centrifugal fans allows them to handle varying air volumes and pressure requirements, while their efficient design helps reduce energy consumption compared to traditional fan types.