I. Pregled

DC gladilni reaktor se uporablja na enosmerni strani pretvornikov, kjer skozi reaktor teče enosmerna tok z izmenično komponento. Njegova funkcija je omejitev izmenične komponente, superponirane na enosmerni tok, znotraj določene vrednosti. Uporablja se tudi za spajanje na enosmerni strani vzporednih invertorjev, da omejuje krožni tok v zanki, za omejitev hitrosti naraščanja toka med prekinjenjem okvare pri enosmernem hitrem stikalu ter za niveliranje enosmerne napetosti v srednjih vezjih invertorjev z virom toka in napetosti. Poleg tega se lahko uporablja tudi v usmerniških napajalnikih za zmanjševanje valovitosti.

Funkcionalnosti produkta:

DC gladska tuljava se uporablja predvsem v tokokrogih za izboljšanje kakovosti električne energije in povečanje faktorja moči. Tuljave, izdelane v naši tovarni, so izdelane iz hladno valjanih pločevin iz silicijevega jekla z natančno obdelavo in sestavljene so predvsem iz jedra in navitja. Jadro običajno uporablja dvojni stolpčni strukturi, ki je sestavljena iz več plasti silicijevih jeklenih listov, ločenih z izolacijskimi ploščami, da se prepreči magnetno nasičenje. Jarm je kvadratnega tipa, po sestavljanju pa se tesno stisne s protinapetostnimi vijaki, da se zmanjša hrup. Ta izdelek je suhe vrste, z lastnim hlajenjem, z dvema razredoma izolacije: razred B in razred F. Značilnosti izdelka so kompaktna velikost, nizek dvig temperature in nizek hrup.

II. Oznaka modela

III. Tehnični parametri delovanja

1、Nazivna obratovalna napetost: DC 500 V – DC 1000 V

2、Dielektrična trdnost: Jedro do navitja zdrži 3000 VAC / 50 Hz / 10 mA / 10 s brez preskoka ali preboja

3、Izolacijski upor: Jedro do navitja ≥100 MΩ pri 1000 VDC

4. Ravni hrupa: manj kot 60 dB (izmerjeno v vodoravni razdalji 1 meter od reaktorja)

5. Skladnost z standardi:

IEC289: 1987 Reaktorji

GB10229-88 Reaktorji (enako IEC289:1987)

JB9644-1999 Reaktorji za polprevodniški električni pogon

IV. Delovni pogoji

1. Temperaturno območje okolice: -25 °C do +45 °C; relativna vlažnost ≤90 %.

2. Brez škodljivih plinov, gorljivih ali eksplozivnih snovi.

3. Okolica naj ima dobro prezračevanje. Če je nameščena v

4. omaro, je treba dodati prezračevalno opremo.

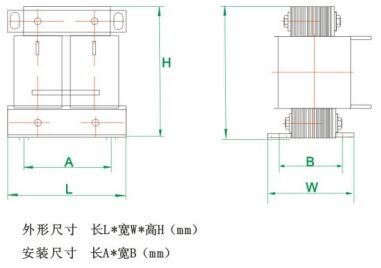

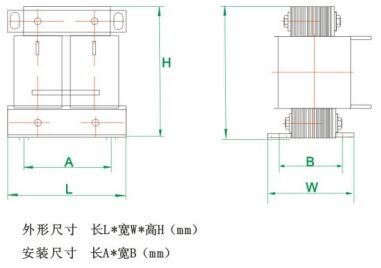

V. Diagrama namestitvenih dimenzij

VI. Tehnični podatki, modeli in tabela dimenzij