1. Overview

When an AC asynchronous motor starts at its rated voltage, the initial starting current is very high, often exceeding 5 to 7 times the rated current. To reduce the starting current and minimize impact on the power grid, a voltage reduction method is typically used for motor startup. Common methods include using reactors or autotransformers. The starting process of an AC motor is brief (usually several seconds to two minutes), after which the voltage-reducing reactor or autotransformer is disconnected. This product is specifically designed for high-voltage asynchronous motor startup, suitable for motors with power ratings from 220 kW to 1400 kW.

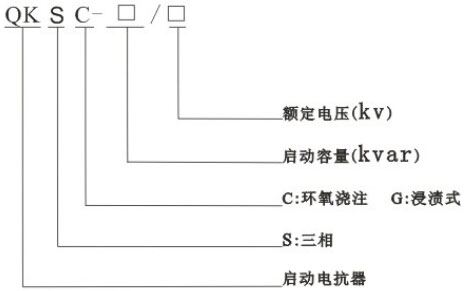

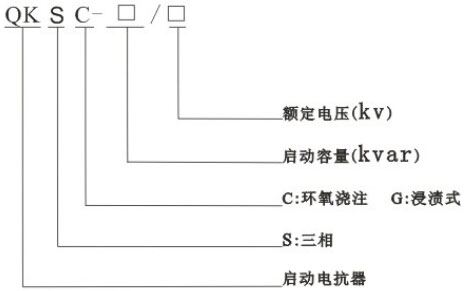

2. Model Significance

3. Structural Features

The QKSC starting reactor uses epoxy casting for optimal insulation performance, ensuring reliability in various operating environments. Key structural features include:

1. The core is made of silicon steel sheets. The core column is divided into evenly spaced segments by multiple air gaps, which are insulated with epoxy laminated sheets to ensure stability over long-term operation.

2. The end surfaces of the core are bonded with steel sheet adhesive, which firmly binds the silicon steel sheets, significantly reducing operational noise and providing excellent corrosion resistance.

3. The coil is epoxy-cast, reinforced with epoxy fiberglass mesh inside and out. Cast under vacuum using an H-class epoxy system, the coil has excellent insulation, high mechanical strength, and can withstand high current impacts and thermal shocks without cracking.

4. The epoxy-cast coil is water-resistant, has low partial discharge, and can operate safely under harsh conditions.

5. The coil ends are equipped with epoxy pads and silicone rubber shock-absorbing pads to effectively reduce vibration during operation.

4. Operating Conditions

1. Altitude: ≤ 1000 m.

2. Ambient temperature: -25℃ to +45℃.

3. Installed indoors in environments free of strong vibrations, harmful gases, conductive or explosive dust, and flammable or explosive materials.

4. If the total startup time reaches 2 minutes (single or cumulative), the reactor must be cooled for 6 hours before the next startup.

5. Performance Parameters

1. Temperature class: FH (180℃).

2. Losses of the dry-type starting reactor are lower than those of oil-immersed reactors.

3. Noise level of the dry-type starting reactor does not exceed industry standards.

6. Customer Ordering Requirements (to be provided in writing)

1. Motor capacity

2. Rated voltage

3. Frequency

4. Rated current

5. Starting current multiple

6. Voltage reduction percentage

7. Startup duration and other relevant parameters

7. Product Specifications and Dimensions