Dry-Type Iron-Core Series Reactor

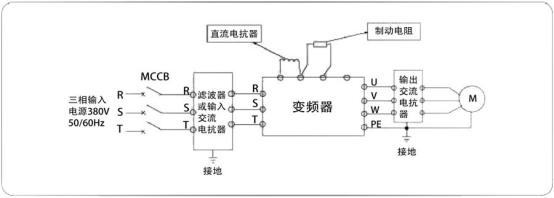

Input and output reactors for variable frequency drive (VFD) systems are designed to protect VFDs and speed controllers. During operation, VFDs and controllers are often subjected to surge currents and surge voltages, which can damage performance and shorten equipment lifespan. Installing an input reactor at the input side suppresses surge voltages and currents, prevents harmonic interference, and extends equipment life.

During variable frequency operation, high-order harmonics and waveform distortions may occur, potentially affecting normal device operation. An output reactor at the output side filters harmonic voltages and currents, improving power quality. Our input and output reactor series are manufactured using high-quality silicon steel sheets with specialized processes, offering compact size, low temperature rise, and noiseless operation.

These reactors are compatible with a wide range of VFD brands, including Siemens, SanKen, Hitachi, Toshiba, Panasonic, Yaskawa, Inovance, Danfoss, Fuji, Eurotherm, LG, Omron, Hyundai, Schneider, Lenze, Emerson, and Conver.

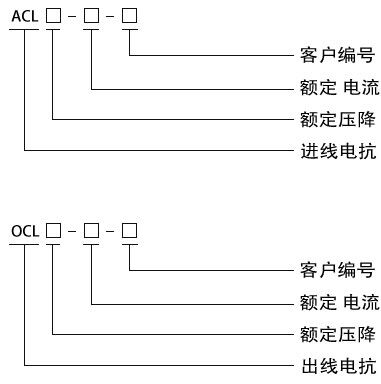

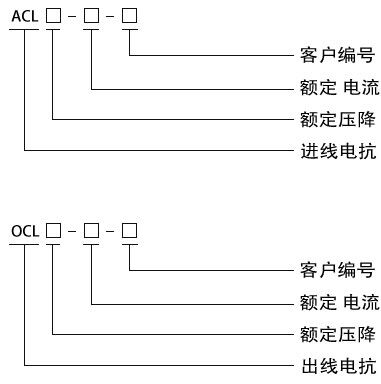

Model Explanation

Product Features

- The power supply may cause noticeable interference to other equipment (disturbances, overvoltage).

- Phase-to-phase voltage imbalance 1.8% of rated voltage.

- Lines with low impedance (power transformers exceeding 10 times the VFD rated value).

- Multiple VFDs installed on a single line to reduce line current.

- Use of power factor correction capacitors or power factor correction units (cosφ).

IV.Operating Conditions

- Altitude: ≤ 1000 meters.

- Ambient temperature: -25°C to +45°C; relative humidity ≤ 90%.

- Ensure proper ventilation; if installed inside cabinets, additional ventilation equipment is required.

Technical Performance Parameters

- Rated operating voltage: 380V/440V, 50Hz

- Rated operating current: 5A to 1600A @ 40°C

- Dielectric strength: Core-to-winding withstand 3000VAC/50Hz/5mA/10s without flashover (factory tested)

- Insulation resistance: ≥ 100 MΩ at 1000VDC

- Reactor noise: < 65 dB (measured at 1m horizontally from reactor)

- Protection class: IP00

- Insulation class: F or higher

- Standards compliance: IEC289:1987 Reactor, GB10229-88 Reactor (equivalent to IEC289:1987), JB9644-1999 Reactor for semiconductor electrical drives

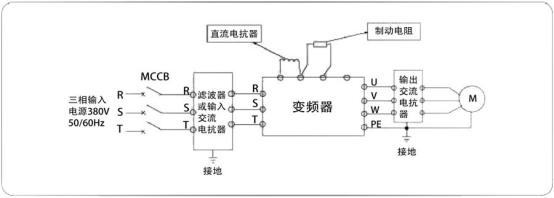

Wiring Methods

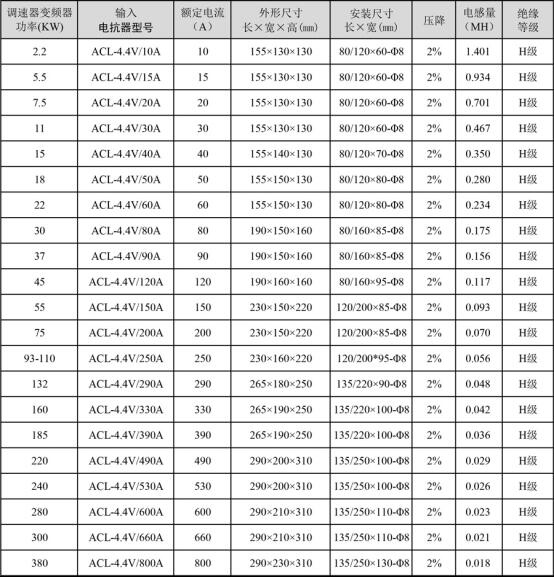

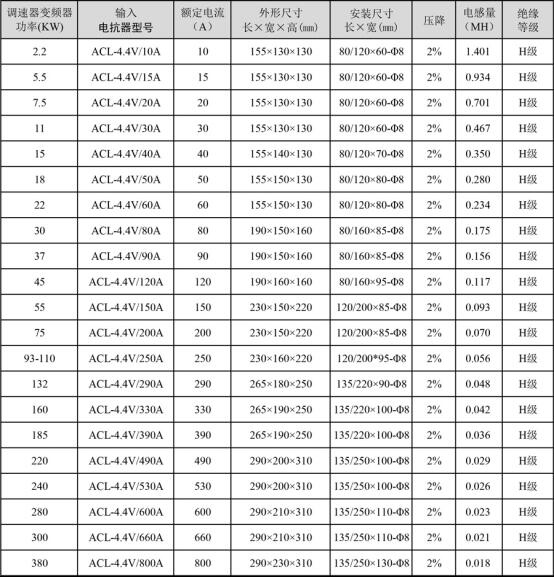

Technical Performance Table

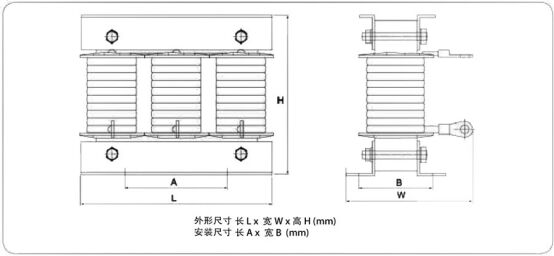

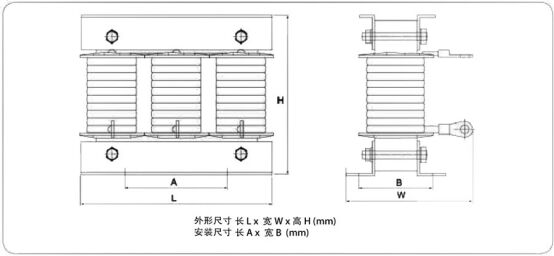

Installation Dimensions Table