Understanding Power Transformer Isolation and Safety Features

Power distribution and control systems rely heavily on transformers for voltage conversion and electrical isolation. The concept of transformer isolation plays a crucial role in ensuring safety and proper functionality across various industrial and commercial applications. Let's explore the key aspects of transformer isolation and how it differs from control transformers in terms of design, purpose, and implementation.

Fundamentals of Transformer Isolation

Physical Isolation Principles

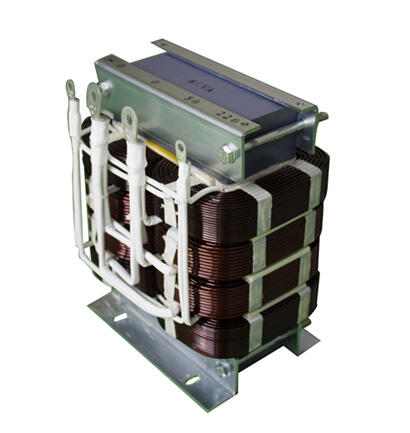

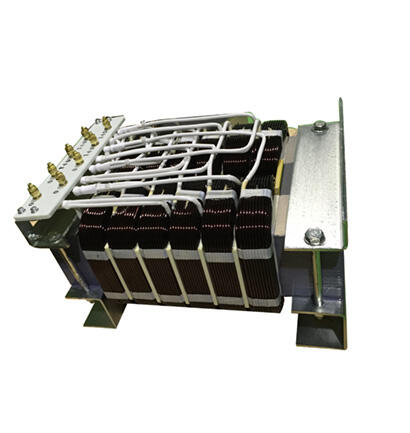

Transformer isolation refers to the physical and electrical separation between the primary and secondary windings of a transformer. This separation is achieved through careful design considerations, including insulation materials and spatial arrangement of the windings around the core. The primary winding receives input power, while the secondary winding delivers the transformed output, with no direct electrical connection between them.

The isolation barrier typically consists of high-quality insulation materials such as specialty papers, varnishes, and air gaps. These materials must withstand voltage stress while maintaining their dielectric properties over extended periods. Modern isolated transformers often incorporate additional safety features like electrostatic shields and reinforced insulation systems.

Benefits of Electrical Separation

The primary advantage of transformer isolation is the prevention of direct current flow between input and output circuits. This separation protects sensitive equipment from harmful voltage spikes and ground loops that could otherwise damage components or create safety hazards. In medical equipment and sensitive measurement devices, transformer isolation helps eliminate electrical noise and ensures accurate operation.

Additionally, isolation transformers provide a degree of protection against electric shock by breaking ground loops and preventing dangerous current paths through the human body. This safety feature is particularly important in environments where personnel might come into contact with electrical equipment.

Control Transformers vs. Isolation Transformers

Design and Construction Differences

While both types serve important functions, control transformers and isolation transformers have distinct design characteristics. Control transformers are primarily designed to maintain consistent output voltage under varying load conditions, making them ideal for powering control circuits and instrumentation. Their construction focuses on voltage regulation and efficiency rather than isolation.

Isolation transformers, conversely, emphasize the quality and effectiveness of their isolation barrier. They typically feature enhanced insulation systems, careful attention to creepage and clearance distances, and often include additional shielding against electromagnetic interference. These design elements result in superior isolation properties but may come at the cost of size and efficiency.

Application-Specific Requirements

Control transformers find extensive use in industrial control panels, automation systems, and machinery where stable voltage supply is critical. They're optimized for handling high inrush currents associated with contactors and solenoids while maintaining output voltage stability. Their compact design and cost-effectiveness make them suitable for these applications.

Isolation transformers, meanwhile, are essential in medical equipment, test instrumentation, and sensitive electronic systems where safety and noise immunity are paramount. Their robust isolation properties make them ideal for protecting both equipment and personnel in demanding environments.

Safety Standards and Compliance

Regulatory Requirements

Transformer isolation must meet specific safety standards depending on the application and jurisdiction. Medical-grade isolation transformers, for example, must comply with stringent requirements regarding leakage current and isolation strength. Industrial applications may have different standards focusing on voltage withstand capabilities and protection against environmental factors.

Common standards include IEC 61558 for general applications, IEC 60601 for medical equipment, and various regional certifications. These standards define minimum requirements for isolation distances, material properties, and testing procedures to ensure reliable operation and safety.

Testing and Certification

Manufacturers must subject their transformers to rigorous testing to verify isolation performance. Standard tests include high-potential (hipot) testing, which applies elevated voltage across the isolation barrier to confirm its integrity. Additional tests measure leakage current, temperature rise, and electromagnetic compatibility.

Regular maintenance and periodic testing of installed transformers help ensure continued safe operation. This includes visual inspections, insulation resistance measurements, and verification of proper grounding connections.

Implementation Considerations

Installation Best Practices

Proper installation of isolated transformers requires careful attention to mounting location, ventilation, and wiring practices. The transformer should be positioned to minimize exposure to moisture, dust, and excessive heat. Adequate clearance must be maintained around the unit to ensure proper cooling and accessibility for maintenance.

Wiring connections must follow manufacturer guidelines regarding conductor size, routing, and termination methods. Proper grounding is essential for safety and optimal performance, with special attention to shield connections in shielded transformers.

Maintenance Requirements

Regular maintenance helps ensure long-term reliability of transformer isolation. This includes periodic inspection of insulation condition, cleaning of cooling surfaces, and verification of electrical connections. Environmental factors such as temperature, humidity, and contamination can affect isolation performance over time.

Documentation of maintenance activities and test results provides valuable historical data for predicting potential issues and planning preventive maintenance. This helps maximize transformer life while maintaining safe and reliable operation.

Frequently Asked Questions

How can I determine if a transformer provides true isolation?

True isolation can be verified through manufacturer documentation showing compliance with relevant standards, physical examination of construction features like separate windings and robust insulation, and electrical testing including hipot and leakage current measurements.

What level of isolation is typically required for medical applications?

Medical applications typically require reinforced isolation meeting IEC 60601-1 standards, with specific requirements for leakage current (typically less than 100 microamps), creepage distances, and voltage withstand capability. Double or reinforced insulation is often mandatory.

How often should isolation transformers be tested?

Isolation transformers should undergo comprehensive testing at least annually, with more frequent inspections in critical applications or harsh environments. Regular visual inspections and basic electrical measurements can be performed quarterly or as part of routine maintenance schedules.