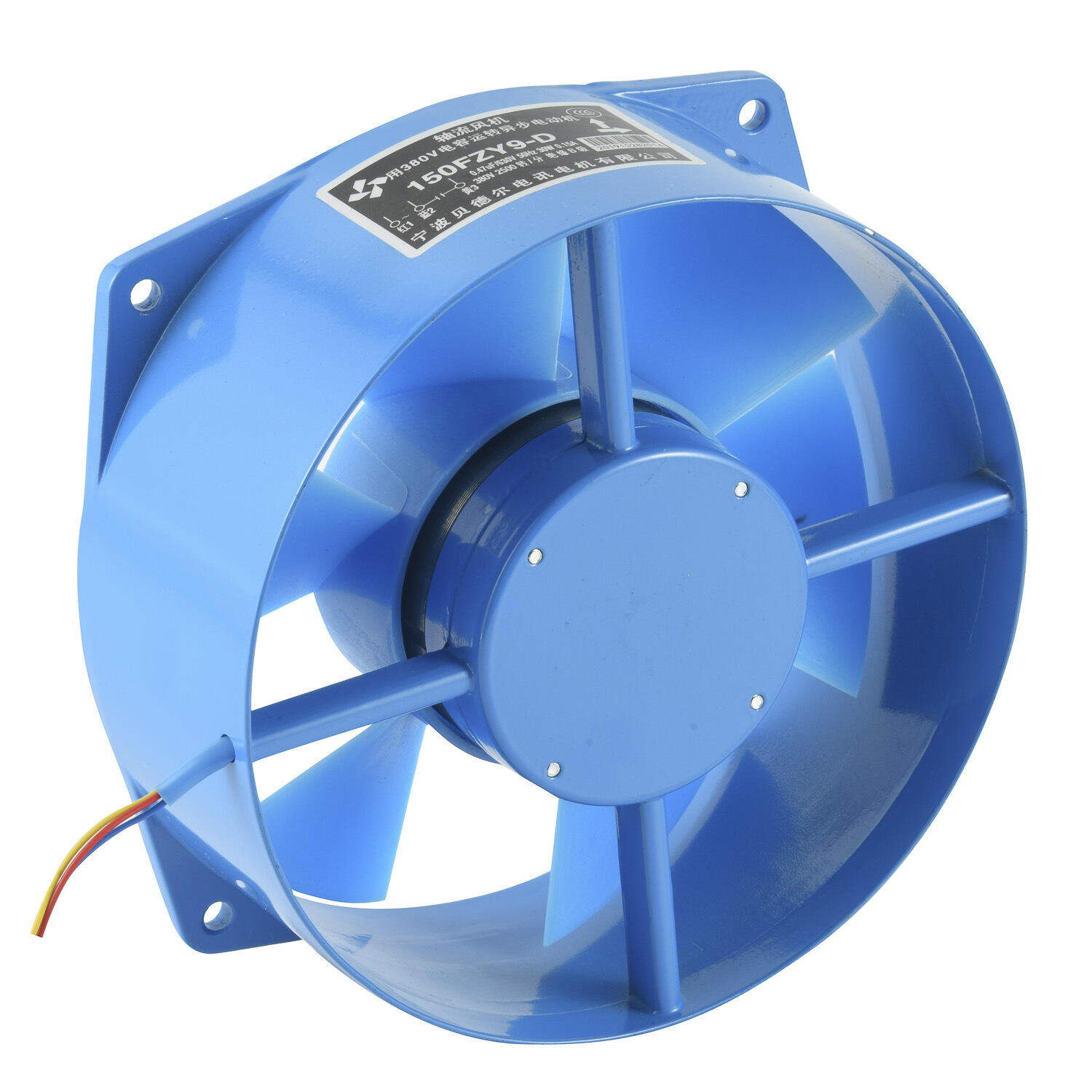

centrifugal fan manufacturer

A centrifugal fan manufacturer specializes in designing, producing, and distributing high-performance air movement solutions for diverse industrial applications. These manufacturers employ cutting-edge engineering principles to create fans that effectively convert mechanical energy into fluid movement through centrifugal force. Their production facilities integrate advanced manufacturing technologies, quality control systems, and precision engineering to ensure consistent product excellence. The manufacturing process encompasses everything from raw material selection to final assembly, incorporating computer-aided design and automated production lines. These manufacturers offer a comprehensive range of centrifugal fans, including backward-curved, forward-curved, and radial blade designs, each optimized for specific applications. Their products serve critical roles in HVAC systems, industrial ventilation, dust collection, material handling, and process cooling applications. Modern centrifugal fan manufacturers emphasize energy efficiency, incorporating innovative aerodynamic designs and premium materials to maximize performance while minimizing power consumption. They also provide customization options to meet specific customer requirements, including specialized impeller designs, housing configurations, and drive systems. Additionally, these manufacturers maintain strict quality control protocols and often hold international certifications, ensuring their products meet or exceed industry standards for safety, reliability, and performance.