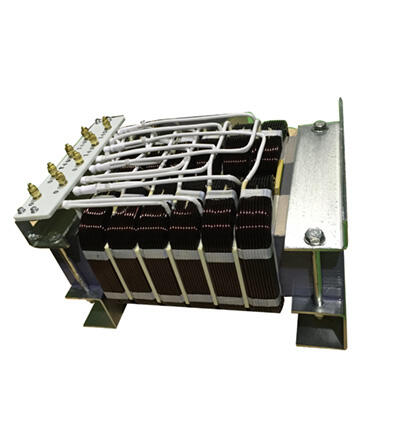

bedryfselktriese waaier

Industriële elektriese fans verteenwoordig 'n hoeksteen van moderne industriële ventilasie- en koelsisteme. Hierdie robuuste toestelle is ontwerp om kragtige lugvloei in eisende omgewings te lewer, deur duursaamheid met hoë-prestasievermoëns te kombineer. Met swaarwagte motors en noukeurig ingenieerde wiele beheer hierdie fans effektief lugcirculasie in groot ruimtes soos magasins, vervaardigingsfasiliteite en industriële komplekse. Die ontwerp sluit gevorderde aerodynamiese beginsels in om lugbeweging te maksimeer terwyl energiegebruik geminimeer word. Hierdie fans kom uitgerus met veranderbare spoedbeheer, wat gestandaardiseerde lugvloei-aanpassing op grond van spesifieke vereistes moontlik maak. Veilighidskenmerke sluit beskermende roosters, termiese oorbelastingbeskerming en geslote draaiings in om betroubare bedryf in streng voorwaardes te verseker. Die konstruksie gebruik gewoonlik industriële materiaalsoorte soos staal of aluminium, wat weerstand bied teen korrosie en slijting. Moderne industriële fans integreer dikwels slim beheer- en monitoreerstelsels, wat draadlose bedryf en onderhoudsbeplanning moontlik maak. Hul veerkantigheid strek tot verskeie toepassings, insluitend ventilasie, hitteverspreiding, rookextraksie en proseskoeling. Die fans is beskikbaar in verskeie monteeropsies, insluitend muurmonteer, plafonmonteer en draagbaarheid, wat buigsaamheid in installasie en implementering aanbied.