3 fasie droë tipe transformator

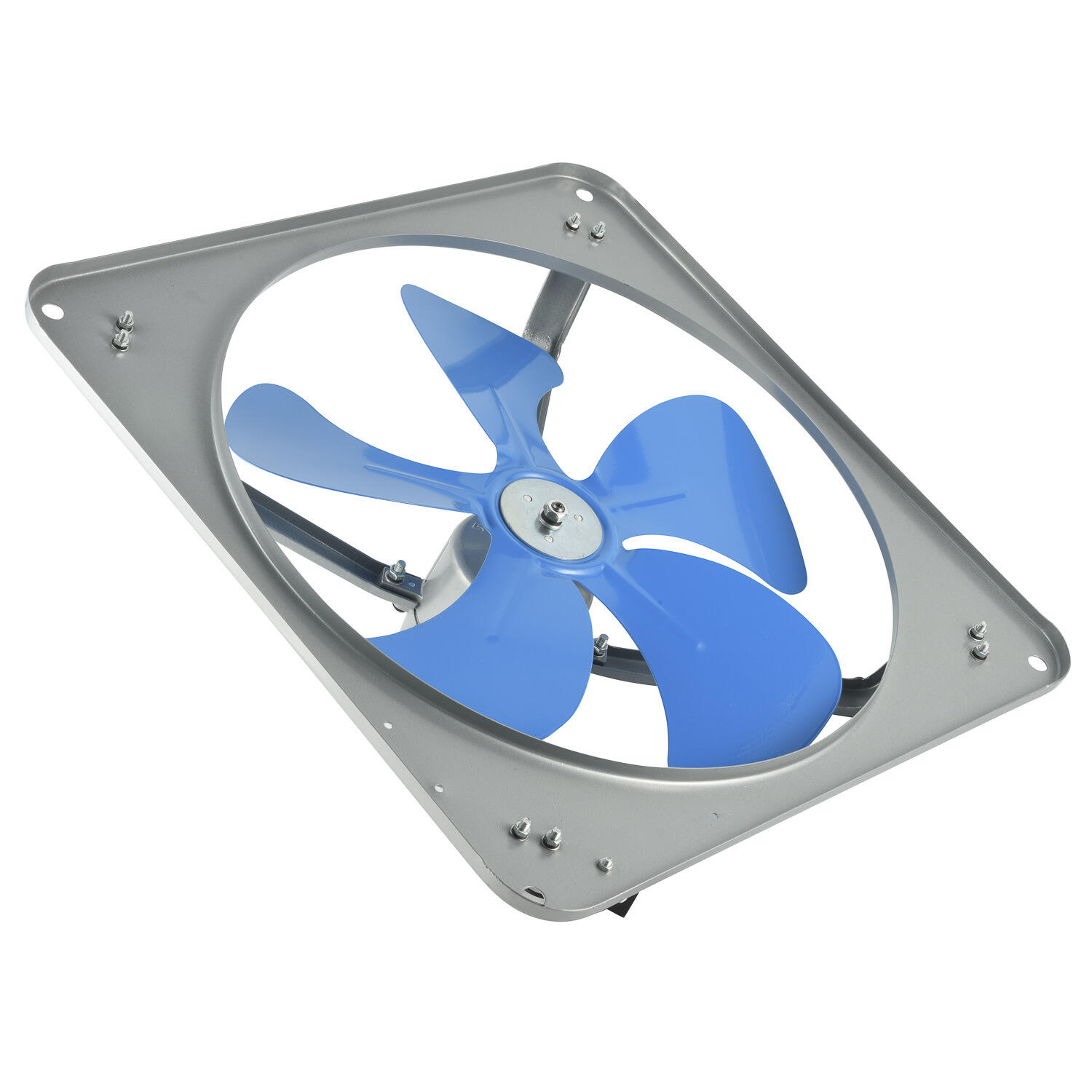

'n 3-fase droë transformator is 'n kruisige elektriese toestel wat ontwerp is om elektriese energie tussen twee skakels deur middel van elektromagnetiese induksie oor te dra, sonder om enige vloeistofkoelmiddel te gebruik. Hierdie transformators funksioneer deur spanningvlakke te konversioneer terwyl dieselfde frekwensie behou word, wat hulle essentieel maak vir stroomdistribusiesisteme. Die kernkonstruksie bestaan tipies uit hoë-graad silikonstaaiele plaatjies, terwyl die windings gemaak word van hoë-reinheid koper of aluminium leiwers wat geïsoleer word met moderne materiaal soos epokshars. Anders as olgevulde transformators, gebruik droë transformators lug vir koeling en het gespesialiseerde ventilasiesisteme om optimale bedryfstemperatuurs te handhaaf. Hulle is ingekonstrueer om belastings te hanteer wat varieer van klein kommersiële toepassings tot groot industriële installasies, tipies beskikbaar in waardes van 50 kVA tot 40 MVA. Die ontwerp sluit gevorderde isolasiesisteme in wat uitstekende termiese en meganiese eienskappe verskaf, wat betroubare prestasie onder verskillende omgewingsomstandighede verseker. Hierdie transformators word veral in binnekantinstallasies, hoogbouwerwe, hospitale en ander plekke waar vuursigtheid en omgewingsverwagtinge primêr is, gehardeer.