Njohja e Rëndësisë së Zgjedhjes së Sensorit të Temperaturës së Saktë

Zgjedhja e sensorit të saktë të temperaturës ka rëndësi të madhe për të gjitha llojet e aplikimeve në të gjitha sektorët e ndryshëm industriale, qofshë gjëra komplekse si pajisjet e prodhimit apo sende të thjeshta që përdorim në mënyrë të përditshme si konsumatorë. Këta sensorë ndihmojnë në matjen e saktë të temperaturave dhe në mbajtjen e kontrollit të duhur, gjë që ka ndikim të madh në funksionimin e sistemeve, sigurinë gjatë përdorimit dhe menaxhimin më të mirë të konsumit të energjisë. Kur bizneset i kushtojnë kohë për të kuptuar çfarë duhet për të zgjedhur sensorin më të përshtatshëm të temperaturës për nevojat e tyre, ato zakonisht arrinë të kursen para në të ardhmen, të evitojnë shpenzimet e panevojshme dhe të kenë rezultate më të besueshme nga operacionet e tyre, pa u ballafaquar vazhdimisht me probleme të papritura.

Llojet e Sensorëve të Temperaturës dhe Zbatimet e tyre

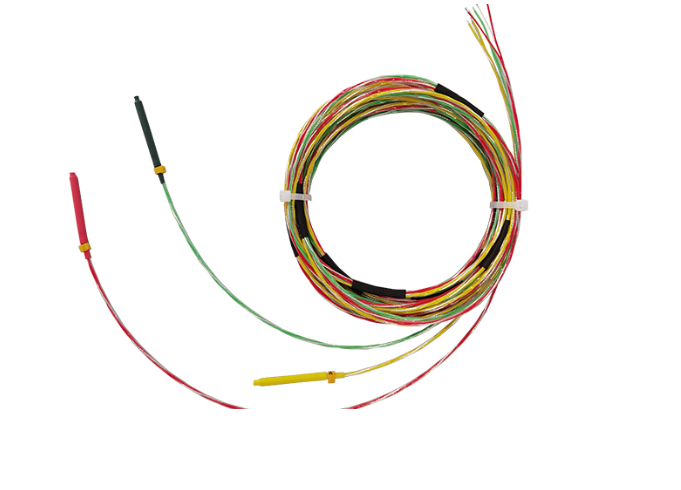

Sot në treg ekzistojnë një larmi sensorësh të temperaturës, nga termokuplat deri te detektorët e temperaturës me rezistencë (RTD), termistorët dhe modele të infrizuarta. Çfarë funksionon më së miri varet nga lloji i punës që duhet kryer. Merrni si shembull termokuplat, ato mund të përballojnë temperatura ekstreme dhe reagojnë shpejt, kështu që fabrikat i duan ato për të monitoruar procese që bëhen shumë të nxehta apo të ftohta. RTD-ja është e ndryshme, këto pajisje të vogla ofrojnë saktësi të qëndrueshme në kohë, kështu që laboratorët dhe spitalet u besojnë shumë atyre. Termistorët? Ata janë mjaft të ndjeshëm por vetëm brenda intervaleve të caktuara, gjë që i bën ata të përshtatshëm për gjëra si makineri për kafë apo termostate në shtëpi. Dhe mos harroni as sensorët e infrizuarë, ata pajisje të mëdha mund të zbulojnë nxehtësinë pa i prekur asgjë, diçka që është e dobishme kur kontrolloni temperaturën e një furrë apo kur kërkoni pika të nxehta në panelet elektrike ku futja e një shtizë do të ishte e pamundur.

Faktorët që duhet të merren parasysh kur zgjidhet një sensor temperaturë

Zgjedhja e sensorit të duhur të temperaturës përfshin shikimin e disa gjërave të rëndësishme në fillim. Zona e temperaturës vjen në mend në të parë, së bashku me saktësinë e nevojshme të leximeve. Gjithashtu është e rëndësishme edhe sa shpejt reagon sensori, veçanërisht kur bëhet fjalë për procese që ndryshojnë shpejt. Disa mjedise thjesht bëhen shumë të nxehta, kështu që kemi nevojë për sensorë që mund të përballen me këto temperatura ekstreme pa u deformuar. Për shembull, për furrat industriale, janë të nevojshme materiale të veçanta që të mbijetojnë nxehtësinë. Kur matjet e sakta janë kritike, si në kërkime shkencore, sensorët me gamë të vogël gabimesh bëhen të domosdoshëm. Gjithashtu është e vërtetë se duhet marrë parasysh edhe sa kohë zgjat sensori nën kushte të ndryshme. A do të qëndrojë në ujë? Të ekspozohet ndaj kimikateve? Përputhshmëria e materialeve bën të gjithë ndryshimin këtu. Dhe, në mënyrë të veçantë, mos harroni rezistencën ndaj stresit fizik, meqenëse shumë sensorë përfundojnë në vende ku mund të goditen ose korrodohen me kalimin e kohës.

Tiparet Kryesore që duhet të kërkohen tek një Sensor i Temperaturës

Larg dhe Larg

Kur flasim për sensorë, saktësia në thelb do të thotë se sa afër matjen e tyre i përgjigjet temperaturës reale. Përpikëria është e ndryshme, megjithatë, sepse ka të bëjë me pyetjen nëse sensori jep përafërsisht të njëjtin rezultat çdo herë kur testohet në kushte identike. Për shumicën e operacioneve industriale ku edhe variacionet e vogla të temperaturës mund të ndikojnë në cilësinë e produktit apo të krijojnë rrezik për sigurinë, është shumë e rëndësishme të përcaktohen saktësisht të dy këto faktorë. Prandaj, kompanitë e mençura shpesh harxhojnë më tepër para për sensorë që vijnë me dokumentacion të kalibrimit të duhur dhe që i përgjigjen standardeve të njohura industriale. Këto dokumente vërtetojnë se pajisja është kontrolluar në mënyrë të duhur në lidhje me pikat e referencës së njohura, gjë që bën të ndryshojë të gjitha kur ka të bëjë me sisteme jetë-kruciale apo procese të shtrenjta prodhimi.

Qëndrueshmëria dhe Rezistenca Mjedisore

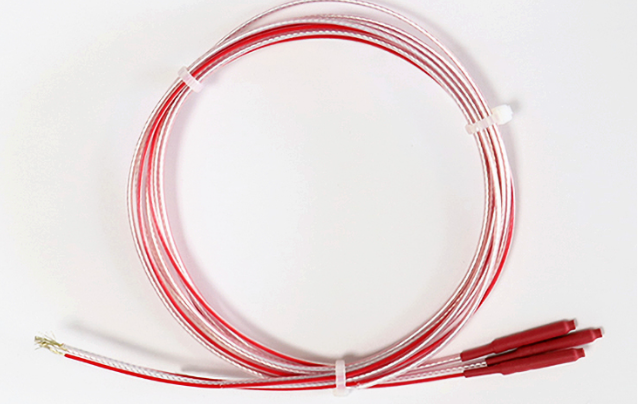

Shumica e sensorëve të temperaturës përfundojnë në vende që nuk janë të lehta, ku ballafaqohen me lloje të ndryshme sfidash si vibracione të vazhdueshme, lagështirë nga uji që shpërndahet kudo, mbledhje pluhuri që e kanë të rëndë, dhe ndonjëherë edhe kimikate që qarkullojnë në ajër. Prandaj është kaq e rëndësishme të zgjidhësh llojin e duhur të mbështjellësit të sensorit. Kur këto pajisje duhet të funksionojnë jashtë ose brenda fabrikave, është e kuptueshme të zgjidhen modele me mbështjellësa të forta nga jashtë. Kërkoni gjithashtu ato që kanë klasifikim kundër futjes së ujit ose depërtimit të pluhurit. Disa prodhues shtojnë shtresa speciale që i rezistojnë ndërrimit në skaj dhe formave të tjera degradimi. Këto tipare jo vetëm që i bëjnë sensorët të zgjasin më gjatë, por edhe të mbajnë saktësinë e matjeve të tyre, pavarësisht nga kushtet e këqija të ambientit që hasin.

Përputhshmëria dhe Integrimi

Kur shikoni në sensore, lloji i daljes së tyre ka shumë rëndësi kur përpiqeni t'i bëni ato të punojnë ngushëllueshëm me sistemet e kontrollit apo pajisjet për mbledhjen e të dhënave. Shumica e sensorëve prodhojnë ose një sinjal të tensionit analogjik, funksionojnë në unaza rrymeje, apo përdorin metoda dixhitale komunikimi si lidhjet I2C apo SPI. Të bësh këtë të drejtë që në fillim e bën jetën shumë më të lehtë në të ardhmen. Një përputhje e gabuar këtu mund të çojë në një sërë problemash gjatë konfigurimit dhe gjetjes së gabimeve më vonë. Prandaj, shumë inxhinierë harxhojnë kohë shtesë në fillim për të kontrolluar përputhshmërinë midis sensorëve të rinj dhe sistemeve me të cilat duhet të lidhen.

Këshilla Praktike për Zbatimin e Sensorëve të Temperaturës

Kalibrimi dhe Mbajtja e Larg

Sensorët e temperaturës kanë nevojë për kalibrime të rregullta nëse duan të vazhdojnë të japin lexime të sakta me kalimin e kohës. Procesi në thelb do të thotë kontrollimin e atij që sensori tregon në lidhje me diçka që e dimë se ka një temperaturë specifike, dhe më pas bëjmë korrigjime kur ka mos përputhje. Sa shpesh kjo duhet të bëhet ndryshon në mënyrë të konsiderueshme në varësi të llojit të sensorit dhe të vendit ku përdoret ai. Disa sensorë industriale mund të kërkojnë kontrollime mujore ndërsa të tjerë mund të qëndrojnë më gjatë midis kalibrimeve. Mbajtja e mirë e regjistrimeve për këto ngjarje kalibruese nuk është thjeshtë dokumentacion - në fakt është e rëndësishme për të kaluar auditimet dhe për të qenë në përputhje me standartet industriale. Shumica e instalimeve zbulon se dokumentacioni i duhur i kursen nga problemet gjatë inspekteve dhe rishikimeve të cilësisë në të ardhmen.

Instalimi dhe Vendosja e Saktë

Instalimi i sensorëve të temperaturës në mënyrë të duhur bën të ndryshojë gjithçka kur bëhet fjalë për mbledhjen e leximeve të besueshme. Vendosja luan një rol të madh në këtë proces. Vendosni sensorin në një vend ku ka qasje të lirë drejt objektit që duhet matur, pa asgjë që të pengojë. Kur keni të bëni me lëngje apo gazra në veçanti, sigurohuni që të ketë kontakt termik të fortë midis sensorit dhe substancës që po matet, sepse kjo e përmirëson funksionimin në përgjithësi. Gjithashtu është e rëndësishme të konsiderohet se sa mirë lënda rrjedh rreth majës së sensorit. Mos e vendosni afër pajisjeve që gjenerojnë nxehtësi të tjera. Dhe keni kujdes për vendet që kanë lëvizje të madhe ajri apo ekspozim në diell, përveç nëse vërtet synohet monitorimi i atyre specifike faktorëve ambientalë për aplikimin e caktuar.

Zgjidhja e problemeve të zakonshme

Nganjëherë leximet e temperaturës mund të jenë të paqarta apo të gabuara. Shkaktarët e zakonshëm përfshijnë lidhje të kabllove të dobëta, elementë të dëmtuar të sensorit ose faktorë të ambientit si ndërhyrja elektromagnetike. Diagnoza e hershme e problemeve dhe disponimi i pjesëve zëvendësuese minimizon kohën e pushimit. Përdorimi i sensorëve me diagnostifikim të brendshëm mund të ndihmojë në zbulimin e dëmtimeve para se ato të ndikojnë në operacione.

Përfundim: Bërja e një Zgjedhjeje të Informuar

Zgjedhja e sensorit të saktë të temperaturës do të thotë se duhet të peshohen aspektet teknike të ndryshme në raport me praktikat reale. Kur dikush di për modele të ndryshme të sensorëve, karakteristikat e tyre dhe mënyrën se si duhet të montohen në fakt, atëherë bëhet e mundur të merren lexime të sakta të temperaturës që i përshtaten nevojave të aplikimit të caktuar. Investimi i disa minutave shtesë para instalimit për të zgjedhur sensorët dhe për t'i mirëmbajtur ato në mënyrë të duhur çon me siguri në kontroll më të mirë të proceseve, kushte më të sigurta dhe eficiencë të përgjithshme operative në të ardhmen.

FAQ

Cila është ndryshesa midis një termokupli dhe një sensori RTD të temperaturës?

Termokuplat matin temperaturën bazuar në ndryshimet e tensionit të gjeneruara në lidhjet e metaleve të ndryshme dhe janë të përshtatshme për temperaturat e larta. RTD-të matin ndryshimet e rezistencës në metale dhe ofrojnë saktësi më të lartë në temperaturat e moderuara.

Sa shpesh duhet të kalibrohen sensorët e temperaturës?

Frekuenca e kalibrimit varet nga përdorimi dhe ambienti, por zakonisht lëviz nga gjashtë muaj në një vit. Aplikimet kritike mund të kërkojnë kalibrime më të shpeshta.

A mund të përdoren sensorët e temperaturës në ambiente të rrezikshme?

Po, por sensorët duhet të kenë certifikime si ATEX ose IECEx dhe të jenë projektuar për të parandaluar burimet e ndezjes.

Cilët faktorë ndikojnë në kohën e përgjigjes së një sensori temperaturë?

Materiali i sensorit, madhësia, përçueshmëria termike dhe ambienti i instalimit të gjithë ndikojnë në kohën e përgjigjes. Sensorët më të vegjël me kontakt termik të mirë përgjigjen më shpejt.