Зах зээлийн эх сурвалжуудын мэдээгээр, NVIDIA компани уг онсгооны хугацаанд АНУ-ын Калифорни мужийн Санта Клар галаар өөрийн төвд хаалттай, хувийн чуулган зохион байгуулах болно. Энэ уулзалтын гол сэдэв бол "Өгөгдлийн төвийн цахилгааны дутагдал"-ын асуудлыг хэлэлцэх, шийдвэрлэх явдал юм энэ нь нийтийн оюун ухааны хөгжлийг саатуулж болзошгүй юм. Энэ чуулган нь цахилгаан ба цахилгаан техникийн салбарт анхаарч ажилладаг эхлэгч компанийн удирдлагуудыг нэгтгэх болно.

Шинжилгээчид ийнхүү дүгнэдэг энэ нь энерги дутагдал нь AI байгууламжийг байгуулахад NVIDIA-ийн чипийг ашигладаг компаниудад үнэхээр нөлөөлж байгааг харуулж байна. Эдгээр компаниудын өгөгдлийн төвүүд нь NVIDIA-ийн 'их хэмжээний цахилгаан эрчим хүч шаарддаг' хиймэл оюун ухааны серверийн чипээр дүүрсэн байдаг бөгөөд цахилгаан хангамжийн хязгаарлалт нь 'хиймэл оюун ухааны хөгжлийг саатуулж болзошгүй'.

Энэ сарын эхэнд Morgan Stanley 2025-2028 онд АНУ-ын өгөгдлийн төвүүдийн нийт цахилгааны дутагдлыг 44 гигаваттаас 47 гигаваттруу нэмэгдүүлсэн. Энэ дутагдал нь 9 Майами хот эсвэл 15 Филадельфи хотын цахилгаан хэрэглээтэй эквивалент юм.

Goldman Sachs өмнө нь AI серверийн кластерууд цахилгаан эрчим хүчийг торны өргөшлөөс хамаагүй хурдан темпаар хэрэглэж байгааг зааж өгсөн бөгөөд цахилгаан хангамж нь AI үед хамгийн том саад болох магадлалтай гэж үзсэн.

EIA-ийн урьдчилсан таамаглалаар 2030 онд өгөгдлийн төвүүдийн цахилгаан эрчим хүчний хэрэгцээ 2023 оныгтой харьцуулахад 150%-аас дээш нэмэгдэх бөгөөд, ухаалаг шинж чанард суурилсан өгөгдлийн төвүүд Нэгдсэн Улсын нийт цахилгаан ачааллын 9%-ийг эзлэх болно. Энэ нь 14 ГВт-ын суурилагдсан чадал дахь хоцрогдолд хүргэх болно. Суурилагдсан чадлын хоцрогдлын эрэлт нь цахилгаан хангамж болон торны тоног төхөөрөмжийг хүчтэй нөлөөлөх болно.

Харин NVIDIA өмнө нь 800V цахилгаан хангамжийн архитектуртай холбоотой цагаан бичиг гаргасан бөгөөд нэг машинд ноогдох энергийн хэрэглээ, хүчдэлийн түвшин нэмэгдсэнээр 800V цахилгаан хангамж, хатуу биеийн трансформатор (SST) зэрэг шинэ технологийн хөгжлийн шаардлагыг удирдан чиглүүлж байна. Тиймээс NVIDIA-ийн хиймэл оюун ухааны цахилгаан эрчим хүчний хомсдолын чуулганыг зохион байгуулах нь Америкийн Нэгдсэн Улсад цахилгаан эрчим хүчний хомсдол явагдаж байгааг илтгэх тодорхой дохио юм. Мөн зэрэгцээгээр хатуу биеийн трансформатор болон дэмжих тоног төхөөрөмжүүд Америкийн Нэгдсэн Улсын зах зээл дээр маш их эрэлт хэрэгцээтэй бүтээгдэхүүн болон хувирч байна.

Шинжилэгчид SST нь 27-р оны II хагас жилд томрох болно гэж таамаглаж байгаа бөгөөд 29-30 онд AIDC-ийн гадаа байрлах цахилгаан хангамжийн голчлон хэрэглэгддэг шийдэл болон хувирна гэж үзэж байна. 2030 онд дэлхийн SST зах зээлийн хэмжээ 100 тэрбум ам.долларыг давах болно.

Трансформер дутагдал нь хэлхээний урвалыг эхлүүлсэн байна. Нэгдсэн Улсын трансформаторуудын 70%-иад нь 25 жилээс дээш хугацаагаар ажиллаж байгаа бөгөөд зарим тоноглолоос 40 жил хүртэл зориулалтын наснаас илүү ажиллаж байгаа нь 2025 онд АНУ-ын нийт трансформаторын 30%-ийн дутагдлыг үүсгэж байна.

АНУ-ын зах зээлээс өөрөөр, европын худалдан авагчдын захидалт дарааллын дуудлага нь Хятадын трансформатор үйлдвэрлэгчдийн өдөр тутмын дуу авиа болсон. Ерөнхий тамгын газрын мэдээллээр Хятадын трансформаторын экспорт 2025 оны есдүгээр сарын эцэст 46.48 тэрбум юань хүрсэн бөгөөд Европын зах зээл жилийн өмнөтэй харьцуулахад 138% өссөн. Америкийн нэгдсэн улсын өгөгдлийн төвүүд ч гэсэн нийлүүлэлтийг хангахын тулд 20% илүү төлбөр төлөхэд бэлэн байна. Олон улсын энерги агентлагийн урьдчилсан тооцоогоор 2030 онд дэлхийн цахилгаан шугамын сүлжээнд хийгдэх хөрөнгө оруулалт АНУ-ын 600 тэрбум долларыг давж гарах болно. Цахилгааны 'дундын буудал' болох трансформаторууд нь хомсдоод байна.

Гадаад зах зээлийн өөрчлөлттэй тулгарч, Хятадын трансформаторын үйлдвэрлэлийн салбар боломжуудыг баримталж, хурдан хариу арга хэмжээ авчээ. Сианын цахилгаан (XIDIAN) доорх трансформаторын 'улсын баг' шийдэмгий арга хэмжээ авчээ. 2025 оны 12-р сарын 10-11-нд Хятадын цахилгаан тоног төхөөрөмжийн ассоциацийн трансформаторын салбарын жилийн баяр наадам болон 'Хувьсгалын тавдугаар жилийн төлөвлөгөө'-тэй танилцах өндөр чанартай хөгжлийн семинар амжилттай зохион байгуулагдсан. Энэхүү хурлыг Хятадын цахилгаан тоног төхөөрөмжийн ассоциацийн трансформаторын салбар зохион байгуулж, XIDIAN-ын доорх Шенигийн трансформаторын институт зэрэг байгууллагууд хамтран зохион байгуулсан.

Конференц нь трансформаторын салбартай 260 гаруй компанид, нийт оролцогчдын тоо 450 гаруй байсан. Чжжао Ёнжи, Сиань Цахилгааны (Хятадын Зүйн Цахилгаан) Ерөнхий нарийн бичгийн дарга, Ерөнхий захирал мөн Хятадын Цахилгаан Тоног төхөөрөмжийн Салбарын Нийгэмлэгийн Трансформаторын Салбарын Дарга энэ хуралд оролцож, ярилцлага хийсэн. Тэрээр дэлхийн энерги системийн гүн зүйлийн хувирлын хамт 'улсын том тоног төхөөрөмж' болох цахилгааны аюулгүй байдлыг хангах үүрэгтэй трансформаторын салбар нь боломжийг барьж авч, цаг хугацааны урсгалд нийцэж, хэмжээ чанарын хувьд зэрэг дэвшсэн гэж үзсэн. Салбар нь шинэчлэлтийг хөгжүүлэх зарчимд үл хөдлөх ба гол технологийг даван туулах ёстой. Өндөр түвшний, цэвэр орчны болон ухаалагжуулалтын чиглэлд анхаарлаа хандуулан экологийн хувьд илүү сайн бүтээгдэхүүний томоохон хэмжээний хэрэглээг хурдасгах, дэвшилтэт мэдрэгч болон ухаалаг алгоритмыг идэвхтэй нэгтгэх ёстой. мөн аж үйлдвэрийн хөгжлийн өндөр цэгийг эзлэхэд төвлөрөн ажиллах шаардлагатай. Түүнчлэн, олон улсын хандлагаа өргөжүүлж, олон улсын өрсөлдөх чадвараа нэмэгдүүлэх шаардлагатай. 'Гадаад руу гарах' ба 'дотогш нь оруулах'-ыг хослуулан олон улсын стандартыг боловсруулах ажилд идэвхтэй оролцож, хятадын технологи, стандарт, тоног төхөөрөмжийг дэлхийд таниулж, Хятадын хувиргаан хувиргалтын салбарын олон улсын нөлөөллийг тасралтгүй нэмэгдүүлэх хэрэгтэй.

Энэхүү хурал Хятадын хувиргааны гадаад зах зээл рүү нэвтрэх асуудлыг маш ихээр анхаарч, «Шинэ чиглэлд анхаарлаа хандуулах, Гадаадын зах зээлийг өргөжүүлэх, аж үйлдвэрийн байршилтыг хурдасгах» сэдвийн онцлох ярилцлагыг тусгайлан зохион байгуулсан. Баодин Тяньвэй Баобянь Цахилгаан ХК-ийн судалгааны хүрээлэнгийн даргын орлогч Ши Жянь; Шаньдонг Цахилгаан Боловсруулалт Бүлгийн Шаньдонг Цахилгаан Инженерчлэлийн & Тоног төхөөрөмжийн ХК-ийн Ерөнхий инженер Занг Сяоянг; Хайнань Цзиньпан Оюуны Технологийн ХК-ийн Техникийн зөвлөх Ван Жунбо; Шэньяний Трансформаторын Судалгааны ХК-ийн Ерөнхий захиралын туслагч Тянь Вэньге нарыг уриалан оролцоогоор, технологийн хүч бололцоо, дэлхий дахины байршил, хамтын ажиллагааны шинэчлэл зэрэг олон талаас трансформаторын салбарт эрчим хүчний хувьсгал болон глобализацийн долгионтой холбоотой өнөөгийн байдлын талаар гүнзгийрүүлэн ярилцсан. эрчим хүчний хувьсгал болон глобализацийн долгионы царайцаас трансформаторын салбарын өнөөгийн байдалд анхаарлаа хандуулсан.

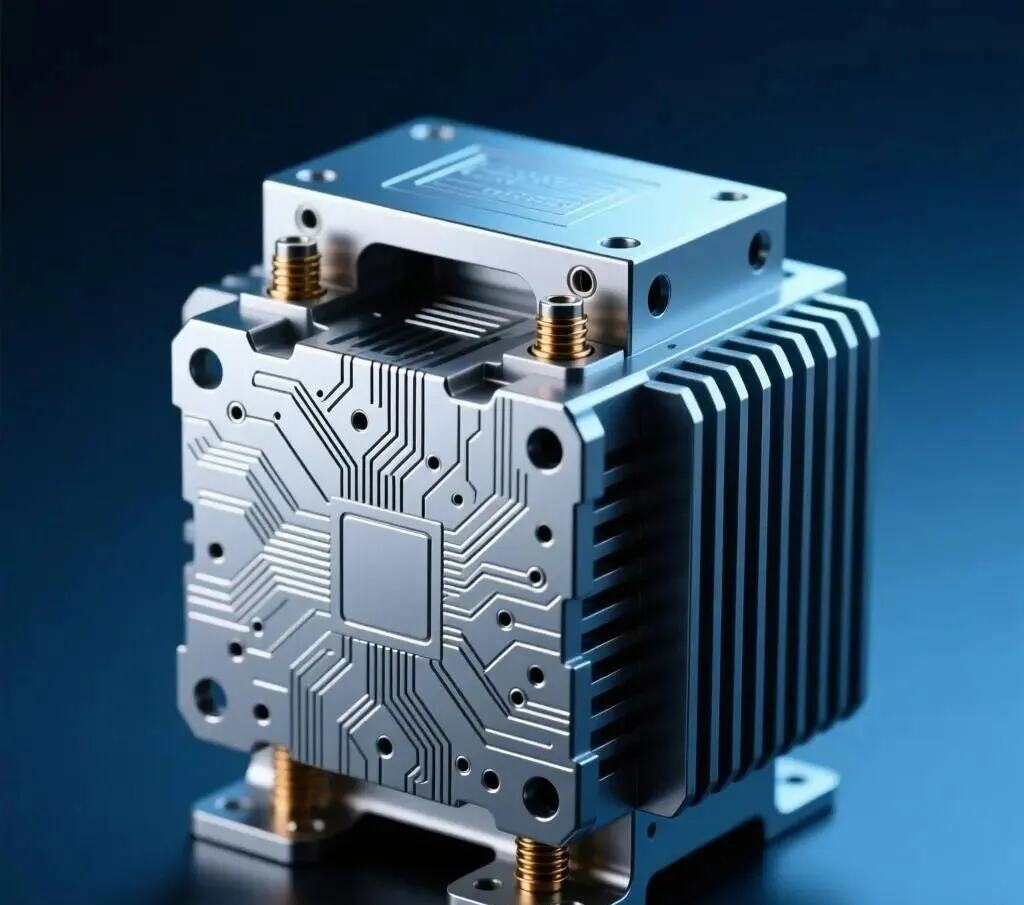

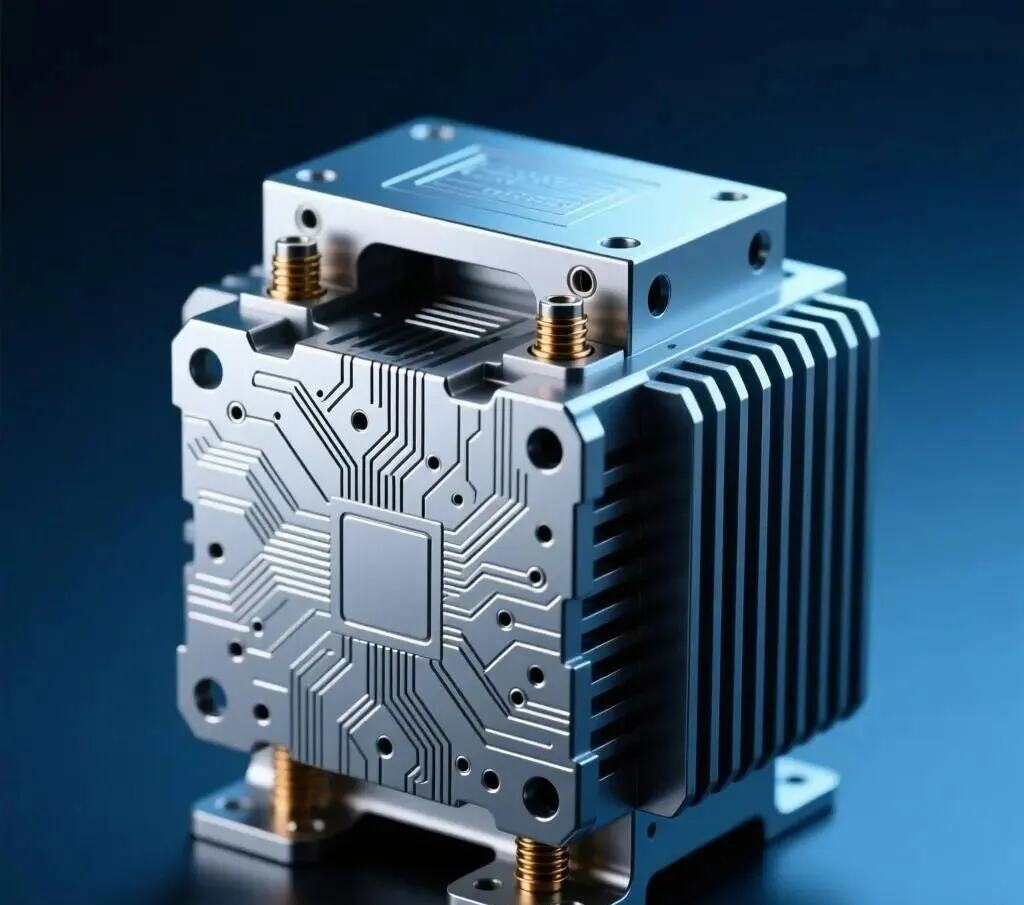

Сүүлийн үед Чину-ын XD Цахилгаан компани улам бүр өндөр хүчдэлийн тоног төхөөрөмж, шинэ эрчим хүчний дэмжлэгийн тоног төхөөрөмж зэрэг салбарт шинжлэх ухаан, технологийн шинэлэг бүтээлдээ "тооны болон чанарын сайжрал" гаргасан. Тусгайлан цахилгаан хангамжийн үндсэн технологийн салбарт "дуурайх" байдлаас "угтах" байдал руу шилжихэд нь хатуу фазын хувиргуу, дэлхийн хамгийн их багтаамжтай уян хатан гүйдлийн хувиргууны амжилтууд чухал үүрэг гүйцэтгэсэн.

Шинэ цахилгаан системийн түлхүүр тоног төхөөрөмж болох Чин XD Цахилгааны дэд үйлдвэр, 2025 онд хатуу төлвийн хувиргагчийн технологийг "судалгаа хөгжүүлэлт"-ээс "масс үйлдвэрлэл"-рүү шилжүүлэх чухал алхамд хүрч, фотовольтаик, өгөгдлийн төв, цэнэглэх станц гэх мэт олон сценаритай бүтээгдэхүүний матрицыг бүрдүүлсэн. Хиймэл оюун ухааны тооцооллын төв болон өгөгдлийн төвүүдийн өндөр цахилгаан хэрэглээ, өндөр зайны шаардлагад зориулан XD Цахилгааны Дигитал Технологийн салбар нь 10 кВ AC-ийг шууд 800 В DC болгон хувиргаж, зуутангийн хүрээнд зууны киловаттаас нэг мегаваттын хүртэл гагнууртай өргөжих боломжийг дэмждэг 800 В DC архитектуртай хатуу төлвийн хувиргагчийг гаргасан. Одоогоор 2.4 МВт-ын хатуу төлвийн хувиргагч нь "Зүүн Өгөгдөл Баруун Тооцоолол" өгөгдлийн төвд ажиллаж эхэлсэн бөгөөд 2 МВт-ын өгөгдлийн төв/цэнэглэх станцын хатуу төлвийн хувиргагч нь Улсын Сүлжээний Компанийн Өндөр Хүчдэлийн Судалгааны Институтаар гуравдагч этгээдийн шалгалтанд хамрагдсан бөгөөд масс үйлдвэрлэлд ороход бэлэн болсон.

Тебиан Электрик Аппаратус Сток ХХК-ийн үл хамааран хөгжүүлсэн SFL цуврал 35 кВ шинэ энергийн хувиргағч нь мөн аНУ-ын UL сертификат, Европын холбооны CE сертификатыг амжилттай авсан. Үүнд, олон улсын итгэмжлэгдсэн байгууллага TUVAUSTRIA-аар шалгагдсан SFL-8800/33 хувиргағчийн хамгийн өндөр энерги хэмнэлтийн индекс (PEI) нь 99.615% бөгөөд европын холбооны хамгийн өндөр энерги хэмнэлтийн түвшинд (2-р түвшин) тавигдах шаардлагыг давуу татах болсон бөгөөд энерги хэмнэх гайхалтай чадварыг харуулсан. Энэ удаад сертификатжуулагдсан SFL цуврал хувиргағчид нь голчлон шинэ энергийн цахилгаан станц, энерги хадгалалтын системийг дэмжих зориулалттай бөгөөд европ, америкийн зах зээл дэх фотогальваник, салхины энерги болон бусад салбарт тавигдах хувиргағчийн эрэлтийг хангах боломжтой.

Сүүлийн үед Шаньдонгийн Цахилгааны компанийн улмаас үйлдвэрлэсэн Чунцин Боруй компанийн бие даан хөгжүүлсэн SFZ-63000\115 трансформаторууд Герман руу албан ёсоор илгээгдсэн. Бүх ажиллагааны илтгэгчид хэрэглэгчийн техникийн шаардлагад илүү сайн нийцэж, Европын Холбооны энгийн стандартыг бүрэн хангасан. Энэхүү илгээлт нь Чунцин Боруй компанийн Германы зах зээлд анх удаа нэвтрэх боломжийг бүрдүүлсэн бөгөөд үйлдвэрлэлийн дээд зэргийн энерги технологийн тоног төхөөрөмжийн чадавхийг олон улсын түвшинд танигдсан гэж үзэж, Европын зах зээлд гүнзгий нэвтрэн байршрах суурийг тавьсан.

Мөн зэрэг Чунцин Боруй компанийн шинэ бүтээгдэхүүн болох SSPF-150000\220 гурван хуваагдсан трансформатор саяхан улсын түвшний үнэлгээг амжилттай давжээ. Энэ бүтээгдэхүүн нь цахилгааны хангамжийн уян хатан чадавхи, ажиллаж буй найдвартай байдлыг, мөн энерги циклийн ашиглалтыг нэгтгэн хослуулсан.

Сүүлийн үед Baobian Electric компани Эфиоп улсад байрлах гидро цахилгаан станц болон Саудын Арабист байрлах шинэ эрчим хүчний төслүүдийн дүнд нийт 23 трансформаторын захидал амжилттай авч, гадаадын гидро цахилгаан салбартой өрсөлдөх чадвартай байдал, мөн шинэ эрчим хүчний зах зээлдээ амжилт гаргасныг харуулсан. Эфиоп улсын Koisha гидро цахилгаан станцын төслийн хүрээнд Baobian Electric бүх өрсөлдөгчдөө давж, цахилгаан станцын 19 ширхэг 400 кВ-ын гол трансформаторын захидлыг авсан. Саудын Арабист байрлах Yanbu салхины цахилгаан станцын төслийн хүрээнд компани 110 кВ-ын 4 ширхэг трансформаторын захидлыг авсан бөгөөд энэ нь Сауд PP15 төслийн дараагийн захидлыг авсан анхны тохиолдол болж, шинэ эрчим хүчний зах зээлдээ түгээн нэвтрэхэд шинэ алхам хийсэн юм.

Гуодиан Нари нь олон улсын стратегийг ч мөн идэвхтэй хэрэгжүүлж байна. Өөрсдөө хөгжүүлсэн тархалтын хувиргағчаа Аргентины зах зээл рүү анх удаа экспортлож, статик хувьсах компенсатор (SVC)-г Мексикийн зах зээлд нэвтрүүлсэн, тархалтын сүлжээний үйлчилгээ, засварын бизнесийг Чилийн зах зээлд нэвтрүүлсэн бол доод хүчдэлийн уян хатамжтай ТС технологийг Гонконгт хэрэглэхэд амжилттай нэвтрүүллээ. Олон улсын бизнес нь Гуодиан Нари-ийн өндөр чанартай хөгжлийн шинэ ашгийн эх үүсвэр болсон.

Түүнчлэн, Баогуан Сток компани удирдаж хөгжүүлсэн BGH7110 вакуум дамжуулагч нь 'вахуум зүрх' гэж үзэж болох бөгөөд CHVT төрлийн хувиргаачийн хувьсах трансформаторын ачааллын өөрчлөгч дээр суурилуулан Лундун-Шаньдонг ±800кВ УВХ ТС дамжуулалтын төслийн хүрээнд албан ёсоор ажиллахаар орсон. Энэ нь зөвхөн дотоодын технологийн цоорхойг л бөглөөгүй, харин хувиргаач, тап чангаруулагчийн хамтлагийн тоног төхөөрөмжийг экспортлох боломжийг ч бүрдүүллээ.

Количествийн хувьд их, чанарын хувьд өндөр байх хэдий ч, Хятадын трансформаторууд нь 'үнэ цэнээрээ сайн' ч гэсэн 'үнээрээ хямд' биш юм. Тайлангийн мэдээгээр 2020 оны үед нэгжид $12,000 байсан Хятадын трансформаторын дундаж экспортод ойшох үнэ 2025 онд нэгжид $20,800 болон өссөн бөгөөд өндөр түвшний загваруудын үнэ хоёр дахин нэмэгдсэн. тус тусын нөхцөл байдлын дагуу захидалт шийдэл нь өрсөлдөх давуу тал болсон: Африкийн төслүүдийг өндөр температур, өндөр чийгшилтэй орчинд зориулан тохируулсан, Европын өгөгдлийн төвүүд ухаалаг удирдлагын системтэй хангасан ба Гуанчжоуд ажиллуулсан дэлхийн анхны 500 кВ ургамлын тосон трансформатор нь гадаадын орчин хамгаалах технологийн монополийг таслан задалсан. 2025 онд Францын цахилгаан компани EDF том Хятадын 50 трансформатор захидалт хийсэн. Европын өгөгдлийн төвүүд ухаалаг удирдлагын системтэй хангасан ба Гуанчжоуд ажиллуулсан дэлхийн анхны 500 кВ ургамлын тосон трансформатор нь гадаадын орчин хамгаалах технологийн монополийг таслан задалсан. 2025 онд Францын цахилгаан компани EDF том Хятадын 50 трансформатор захидалт хийсэн. жилийн худалдан авалтын эзлэх хэмжээний гурван хэсгийг эзэлсэн.