Understanding Power Management Through Control Transformers

Control transformers are essential components in modern electrical systems, serving as the backbone of voltage regulation and power distribution. These specialized devices play a crucial role in maintaining stable voltage levels and ensuring the smooth operation of various industrial and commercial applications. By understanding how control transformers work and their diverse applications, businesses can optimize their power management systems and achieve greater operational efficiency.

Fundamental Operating Principles of Control Transformers

Electromagnetic Induction Process

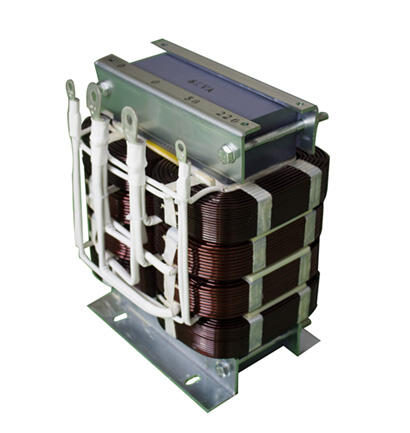

Control transformers operate on the principle of electromagnetic induction, where electrical energy is transferred between two or more circuits through a common magnetic field. The primary winding receives input voltage and creates a magnetic flux in the transformer's core. This flux then induces voltage in the secondary winding, allowing for precise voltage transformation based on the turns ratio between the windings.

The core of control transformers is typically constructed from high-grade silicon steel laminations, which help minimize energy losses and maintain high efficiency. This specialized construction enables control transformers to handle varying loads while maintaining excellent voltage regulation and minimal voltage drop under load conditions.

Voltage Regulation and Load Management

One of the primary functions of control transformers is maintaining stable output voltage despite fluctuations in input voltage or load conditions. This is achieved through careful design of the transformer's magnetic circuit and precise control of the turns ratio. The regulation characteristics of control transformers ensure that sensitive equipment receives consistent power supply, preventing damage and maintaining optimal performance.

Advanced control transformers incorporate features such as electrostatic shielding and specialized winding configurations to minimize harmonic distortion and suppress electrical noise. These design elements are crucial for protecting sensitive electronic equipment and ensuring reliable operation in industrial environments.

Industrial Applications and Implementation

Manufacturing Process Control

In manufacturing facilities, control transformers are integral to automated production systems. They provide stable power supply to programmable logic controllers (PLCs), sensors, and other control devices that require precise voltage levels. The reliability of control transformers ensures continuous operation of assembly lines and reduces the risk of production interruptions due to power-related issues.

Modern manufacturing plants often utilize multiple control transformers in different zones to maintain optimal voltage levels throughout the facility. This distributed approach helps minimize power losses and ensures that each section of the production line receives appropriate power supply for its specific requirements.

Building Automation Systems

Control transformers play a vital role in building automation systems, powering everything from HVAC controls to security systems. These applications require stable, clean power supply to maintain accurate operation of sensors, actuators, and control panels. The isolation provided by control transformers also helps protect sensitive electronic components from power surges and electrical noise.

Smart buildings increasingly rely on sophisticated control systems that demand precise power management. Control transformers enable the integration of various building management functions while ensuring electrical safety and system reliability.

Specialized Features and Design Considerations

Temperature Management Solutions

Modern control transformers incorporate advanced thermal management features to maintain optimal operating temperatures. This includes enhanced cooling systems, temperature monitoring devices, and thermal protection mechanisms. Proper temperature management is crucial for extending the transformer's lifespan and ensuring consistent performance under varying load conditions.

Design engineers must carefully consider factors such as ambient temperature, load profiles, and installation environment when selecting control transformers. These considerations help determine the appropriate cooling method and thermal protection requirements for specific applications.

Protection and Safety Features

Control transformers are equipped with various protection features to ensure safe operation and prevent damage to connected equipment. These include short circuit protection, overcurrent protection, and thermal overload protection. Advanced models may also include monitoring capabilities that provide real-time status updates and alert operators to potential issues.

Safety considerations extend to the physical design of control transformers, with features such as finger-safe terminals, proper insulation, and robust enclosures. These elements help prevent accidental contact with live components and ensure compliance with relevant safety standards.

Installation and Maintenance Best Practices

Proper Installation Guidelines

Successful implementation of control transformers begins with proper installation. This includes selecting an appropriate location with adequate ventilation, securing the transformer properly, and ensuring correct electrical connections. Proper installation practices help maximize performance and minimize the risk of operational issues.

Installation considerations must also account for environmental factors such as humidity, dust, and vibration. Protective enclosures and mounting systems should be selected based on these environmental conditions to ensure long-term reliability.

Preventive Maintenance Strategies

Regular maintenance is essential for ensuring the continued reliable operation of control transformers. This includes periodic inspection of connections, cleaning of cooling surfaces, and monitoring of operating parameters. Implementing a comprehensive maintenance program helps identify potential issues before they lead to equipment failure.

Maintenance schedules should be tailored to the specific application and operating conditions of each control transformer. This may include regular testing of insulation resistance, monitoring of operating temperatures, and inspection of protective devices.

Future Trends and Technological Advancements

Smart Integration Capabilities

The future of control transformers lies in their integration with smart systems and Industry 4.0 technologies. Advanced monitoring capabilities, digital interfaces, and remote management features are becoming increasingly common. These innovations enable better control and optimization of power distribution systems.

Smart control transformers can provide real-time data on operating conditions, energy consumption, and system performance. This information helps facility managers make informed decisions about power management and maintenance scheduling.

Energy Efficiency Improvements

Ongoing developments in materials and design techniques are leading to more energy-efficient control transformers. New core materials, improved winding designs, and advanced cooling systems contribute to reduced losses and higher operating efficiency. These improvements help organizations reduce energy costs and meet sustainability goals.

The focus on energy efficiency extends to the development of eco-friendly insulation materials and manufacturing processes. These advances align with global initiatives for reducing environmental impact while maintaining high performance standards.

Frequently Asked Questions

What factors should be considered when selecting a control transformer?

When selecting a control transformer, consider factors such as input and output voltage requirements, load capacity, environmental conditions, protection features, and regulatory compliance. The application's specific needs, including duty cycle and power quality requirements, should also guide the selection process.

How often should control transformers be maintained?

Control transformers should undergo regular maintenance at least annually, with more frequent inspections in demanding applications or harsh environments. The maintenance schedule should include visual inspections, electrical testing, cleaning, and verification of protection systems.

What are the signs of a failing control transformer?

Common signs of transformer failure include unusual noise or vibration, excessive heating, degraded insulation resistance, unstable output voltage, and tripping of protection devices. Regular monitoring and testing can help identify these issues early and prevent unexpected failures.

Table of Contents

- Understanding Power Management Through Control Transformers

- Fundamental Operating Principles of Control Transformers

- Industrial Applications and Implementation

- Specialized Features and Design Considerations

- Installation and Maintenance Best Practices

- Future Trends and Technological Advancements

- Frequently Asked Questions