Understanding How Temperature Sensors Work

We find temperature sensors all over the place in our lives, whether we're talking about big industrial setups or just regular household stuff. They control everything from keeping our AC running right to making sure our oven hits the correct heat level, and they also prevent machines from overheating which could cause serious damage. What's interesting is that even though these little gadgets aren't much bigger than a thumbtack, they actually work based on some pretty solid science principles combined with clever engineering tricks. The result? Relatively accurate temperature measurements that most people take for granted every single day without really thinking about them.

What Is a Temperature Sensor?

A temperature sensor is a device that detects and converts temperature into a measurable electrical signal. This information is then interpreted by controllers, meters, or monitoring systems. Different types of temperature sensors use different materials and mechanisms to sense thermal changes, but all aim to provide accurate, real-time data.

Common Types of Temperature Sensors and Their Principles

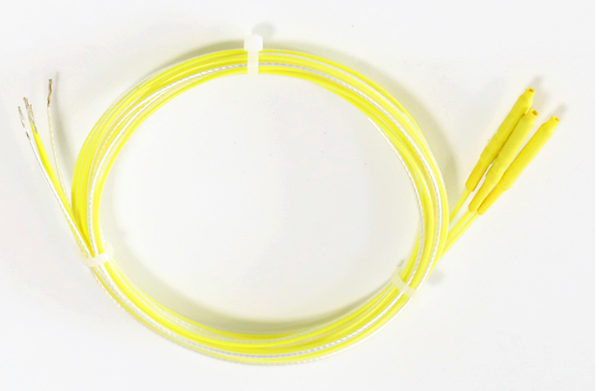

Thermocouples

Thermocouples work because of something called the Seebeck effect. Basically, if we take two different kinds of metal, join them together at one end, then expose that junction to varying temperatures, it creates an electric voltage that's directly related to how big the temperature difference actually is. What makes thermocouples so popular? Well for starters, they're pretty tough little devices. Plus, their cost is relatively low compared to other options out there. And best of all, these temperature sensors can handle everything from super cold environments down to extremely hot conditions. No wonder why factories across industries rely heavily on thermocouples day in and day out for monitoring processes where temperature control matters most.

Resistance Temperature Detectors (RTDs)

RTDs rely on the principle that the resistance of a metal, usually platinum, increases with temperature. By measuring the resistance of the sensor element, the temperature can be inferred. RTDs are highly accurate and stable over time, making them ideal for laboratory and precision applications.

Thermistors

Thermistors are temperature-sensitive resistors. Unlike RTDs, thermistors are made from ceramic materials and exhibit a more dramatic change in resistance with temperature. They are commonly used in consumer electronics and medical devices due to their low cost and responsiveness over narrow temperature ranges.

Infrared Sensors

Infrared temperature sensors detect the thermal radiation emitted by objects. They are non-contact sensors, ideal for measuring the temperature of moving parts or hazardous surfaces. Infrared sensors are useful in applications where physical contact is not possible or practical.

Key Components of a Temperature Sensor

Sensing Element

This is the core of any temperature sensor. Whether it's a thermocouple junction, platinum coil, or ceramic bead, the sensing element reacts to thermal changes and initiates the measurement process.

Signal Conditioning Circuit

Raw signals from the sensing element are usually weak and nonlinear. Signal conditioning circuits amplify, filter, and convert these signals into a usable form, often voltage, current, or digital output.

Output Interface

Depending on the application, the sensor may output data in analog (voltage or current) or digital (I2C, SPI, or UART) formats. The choice depends on how the sensor is integrated with other systems.

Where Temperature Sensors Are Used

Industrial Applications

Temperature sensors are essential in process control, manufacturing, and energy management. In chemical plants, they ensure reactions occur under safe thermal conditions. In power plants, they monitor equipment to prevent overheating and energy loss.

Consumer Electronics

Home appliances like ovens, refrigerators, and thermostats use temperature sensors to maintain comfort and efficiency. Even smartphones include thermal sensors to prevent overheating during intensive tasks.

Automotive Industry

Modern vehicles employ multiple temperature sensors to monitor engine temperature, exhaust gases, cabin climate, and battery packs. These sensors contribute to safety, performance, and emissions control.

Healthcare and Medical Devices

Digital thermometers, incubators, and diagnostic devices depend on accurate temperature sensing to ensure patient safety and effective treatment.

How Temperature Is Measured and Interpreted

Analog Sensors

Analog sensors provide a continuous voltage or current signal that varies with temperature. These require calibration and often signal conditioning to ensure accurate readings. Thermocouples and RTDs typically fall into this category.

Digital Sensors

Digital temperature sensors include onboard electronics that process the signal internally and transmit temperature readings in digital form. These are easier to interface with microcontrollers and are less prone to noise and signal degradation.

Accuracy and Calibration

Accuracy varies depending on the sensor type, quality, and calibration. Regular calibration is crucial in high-precision applications like laboratories or quality assurance environments. Sensors may drift over time, especially when exposed to harsh environments.

Benefits of Using Temperature Sensors

Real-Time Monitoring

Temperature sensors provide instant feedback, allowing systems to respond quickly to temperature fluctuations. This is essential for process optimization and fault prevention.

Automation and Control

In smart systems, temperature sensors trigger automatic responses. For instance, if a motor overheats, a sensor can shut it down or reduce its load to prevent damage.

Safety and Reliability

Maintaining appropriate temperatures ensures equipment runs safely and reduces the risk of fires, explosions, or material degradation.

Choosing the Right Sensor for Your Application

Selecting a temperature sensor depends on several factors: temperature range, desired accuracy, environment (e.g., corrosive, high-vibration), response time, and compatibility with control systems. For example, a thermocouple may be ideal for a furnace, while a thermistor may suit a home thermostat.

FAQ

What is the most accurate type of temperature sensor?

RTDs, especially platinum-based ones, are known for their high accuracy and stability, making them ideal for precision applications.

Can temperature sensors measure both hot and cold conditions?

Yes, depending on the sensor type. Thermocouples, RTDs, and thermistors can all measure a wide range of temperatures from sub-zero to extreme heat.

Do temperature sensors need calibration?

Yes. For consistent and accurate readings, regular calibration against a known temperature standard is recommended, particularly in industrial or scientific settings.

Are non-contact temperature sensors reliable?

Infrared sensors are reliable when used correctly. They require proper calibration and consideration of surface emissivity for accurate measurement.

Table of Contents

- Understanding How Temperature Sensors Work

- Common Types of Temperature Sensors and Their Principles

- Key Components of a Temperature Sensor

- Where Temperature Sensors Are Used

- How Temperature Is Measured and Interpreted

- Benefits of Using Temperature Sensors

- Choosing the Right Sensor for Your Application

- FAQ