Защо точността е важна при измерването на температурата

Контролът на температурата е от голямо значение за всички видове съвременни системи днес, независимо дали става дума за автоматизирани производствени фабрики или за машини, използвани в болници. Истината е, че един температурен сензор не струва много, ако не дава последователни резултати при всяко измерване. Когато сензорите започнат да дават грешни стойности, настъпват сериозни проблеми. Качеството на продукта пада, сметките за енергия се увеличават, защото системите работят по-усилено от необходимото, а в най-лошия случай може да има реални проблеми с безопасността. Затова получаването на точни измервания трябва да бъде основен приоритет за всеки, който отговаря за правилното функциониране на оборудването.

Влияние на неточните измервания на температурата

Дори малки отклонения в показанията на сензорите могат да имат сериозни последици. В производството няколко градуса грешка могат да съсипят цели серии от температурно чувствителни материали. В медицинската област неточни данни за температурата на пациент може да доведат до погрешни диагнози. Прецизността и последователността не са по избор – те са основни изисквания.

Основни фактори, които влияят на точността на сензорите за температура

Тип и конструкция на сензора

Температурните сензори идват в различни форми, като всеки от тях има собствен профил на точност. RTD-тата (съпротивителни температурни детектори), особено направените от платина, се отличават с изключителна прецизност и дългосрочна стабилност. Термисторите работят добре в определени температурни диапазони, но често губят надеждност, когато се използват извън тези граници. И накрая, термопарите. Тези малки работни коне са издръжливи и подходящи за повечето среди, въпреки че обикновено не постигат точността на другите опции, освен ако не се използват заедно с някаква компенсаторна електроника, която коригира измерванията им.

Качество на калибрацията

Фабричната калибрация гарантира, че температурният сензор отговаря на първоначалните си спецификации за точност. Въпреки това с течение на времето сензорите се отклоняват вследствие на термичен цикъл, стареене и излагане на неблагоприятни условия. Редовната повторна калибрация е от съществено значение за поддържане на точността, особено в критични приложения.

Метод за инсталиране

Неправилната инсталация на сензори може да доведе до значителни грешки. Сензорите трябва да се поставят на места, където могат точно да отразяват температурата на обекта, без да се подлагат на топлинни радиатори, въздушни течения или топлинно закъснение. Контактът трябва да е стабилен, особено при повърхностно монтирани сензори, а когато е необходимо, трябва да се използва топлопроводящ паста или изолационни материали.

Обработка на сигнала и интерференция

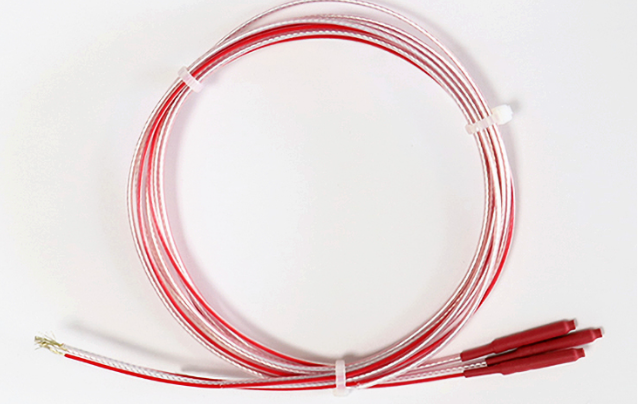

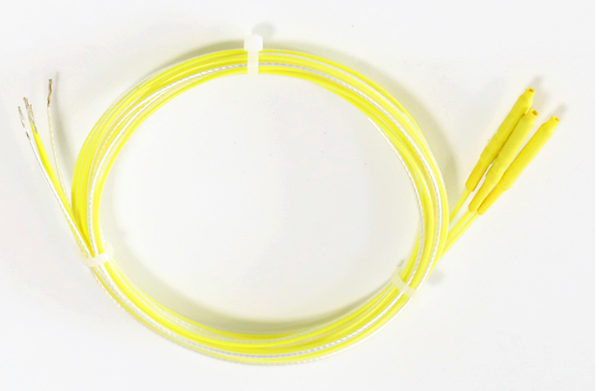

В аналоговите сензори, слабите електрически сигнали трябва да се усилват и преобразуват. Лошо екраниране, електрически смущения или нестабилни захранващи източници могат да изкривят данните. Използването на подходящи вериги за обработка на сигнала и екранирани кабели намалява грешките, предизвикани от външни смущения.

Най-добри практики за осигуряване на точност на температурните сензори

Избор на подходящ сензор за приложението

Точността силно зависи от избора на подходящия сензор за оперативната среда. За високопрецизни измервания в стабилна среда, платинените термометри съпротивление (RTD) често са най-добрият избор. За бързи и икономически изгодни измервания в тесни диапазони, термисторите може да са достатъчни. При измерване в условия на висока температура или индустриална среда, термоеелементите предлагат издръжливост с добро ниво на точност.

Редовна калибрация

Графикът за калибрация трябва да се определя въз основа на чувствителността на приложението и околната среда. Някои индустрии, например фармацевтичната или авиокосмическата, изискват документирана калибрация през фиксирани интервали. Калибрацията трябва да е проследима към национални или международни стандарти и по възможност да се извършва със сертифициран калибрационен инструмент.

Използване на цифрови сензори

Цифров температурни датчици предоставят вградена обработка на сигнала, което минимизира изкривяването и шума на аналоговия сигнал. Изходите им са по-устойчиви към външни смущения и осигуряват последователни показания между различни устройства. Те са особено полезни във вградени системи и битова електроника.

Минимизиране на грешките при предаване на топлина

При контактно измерване на температура, осигурете сензорът да има оптимален термичен контакт с измерваното тяло. Използвайте термично провеждащи материали където е необходимо и избягвайте измерване във въздушни джобове. За приложения с потапяне, сондата трябва да бъде напълно потопена и позиционирана за точно измерване на температурата на течността.

Поставяне на сензора и околната среда

Избягвайте източници на топлина или въздушни течения

Не поставяйте сензори близо до нагревателни елементи, изпускателни отвори или зони с резки промени във въздушния поток. Тези елементи могат да създадат подвеждащи температурни градиенти.

Контрол на околните условия

За по-точни измервания, особено при чувствителни приложения, трябва да се контролира влажността, електромагнитните полета и нивата на вибрации. В някои случаи може да се наложи допълнителна екранировка или защитни обвивки.

Напреднали техники за подобряване на точността

Използване на референтни сензори

При приложения, изискващи дългосрочна точност, използването на референтен сензор заедно с оперативни сензори позволява взаимопроверка и корекция в реално време.

Усредняване и филтриране на сигнала

Програмни техники за филтриране, като плаващи средни стойности или експоненциално изглаждане, помагат да се намали влиянието на преходни пикове и случайни смущения, което води до по-стабилни измервания.

Алгоритми за компенсиране

За термопарите компенсацията на студеното съединение е от съществено значение. Много съвременни системи включват вградени компенсаторни вериги, които коригират влиянието на температурата на околната среда.

Мониторинг и диагностика

Непрекъснато самостоятелно тестване

Някои напреднали сензори включват функции за диагностика, които следят представянето им във времето. Могат да се активират сигнали за предупреждаване, когато точността се отклони извън допустимите граници.

Регистрация на данни

Записването на температурни тенденции помага за идентифициране на деградацията на сензорите на ранен етап. Когато сензорът покаже резки отклонения или модели на дрейф, може да бъде планирана неговата преустановка за калибрация или подмяна, преди напълно да се повреди.

Съвети за точност, специфични за приложението

Промишлено производство

Точността е жизненоважна за постигане на съгласуваност в процесите на отопление, охлаждане или вулканизиране. Изберете сензори, подходящи за висок брой топлинни цикли, и ги монтирайте със стабилни механични интерфейси.

HVAC Системи

Дори грешка от няколко градуса в управлението на климатичните системи може да доведе до неефективно използване на енергия. Използвайте добре калибрирани сензори с добро топлинно съприкосновение и ги поставяйте на подходящо място, далеч от слънчева светлина или вентилационни отвори.

Медицинско оборудване

За безопасността на пациентите изберете цифрови сензори с висококачествени изходни сигнали и използвайте излишък (резервност) в критични приложения. Винаги калибрирайте според медицинските стандарти.

Електроника и полупроводници

Прецизният температурен контрол е критичен за производството и тестването. Използвайте екранирани сензори с висока скорост на отклик и ги поставяйте близо до източници на топлина или чипове.

ЧЗВ

Колко често трябва да се калибрират температурните сензори?

Това зависи от приложението и околната среда. Критични системи може да изискват ежегодна или дори тримесечна калибрация. По-малко чувствителни приложения могат да се калибрират отново на всеки две до три години.

Какъв тип температурен сензор е най-точен?

Платинените термометри със съпротивление (като PT100) са сред най-точните и стабилни с течение на времето, особено в контролирани среди.

Могат ли температурните сензори да губят точност с времето?

Да. Отклонението на сензорите, предизвикано от остаряване, термични цикли и въздействие на околната среда, може да намали точността. Препоръчва се редовна прециклибрация.

Цифровият сензор по-точен ли е от аналоговия?

Не задължително. Цифровите сензори са по-малко податливи на шум, но точността им зависи от качеството на сензора и калибрацията на борда. Аналоговите сензори могат да бъдат много точни при подходящо кондициониране на сигнала и калибрация.

Съдържание

- Защо точността е важна при измерването на температурата

- Основни фактори, които влияят на точността на сензорите за температура

- Най-добри практики за осигуряване на точност на температурните сензори

- Поставяне на сензора и околната среда

- Напреднали техники за подобряване на точността

- Мониторинг и диагностика

- Съвети за точност, специфични за приложението

- ЧЗВ